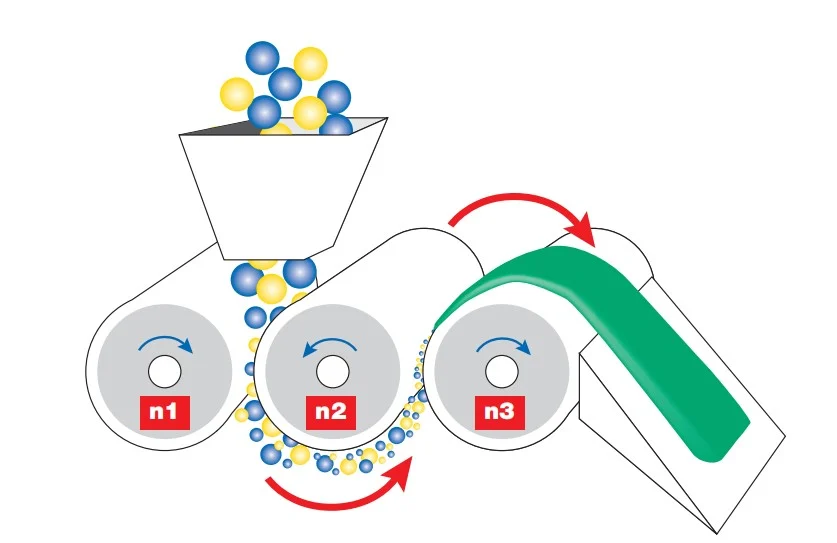

- A three roll mill or triple roll mill a machine that uses to combine, refine, disperse, or homogenize viscous materials

- A three roll mill employs the use of shear force produced by three horizontally arranged rolls that rotate in opposite directions and different speeds relative to each other.