A three roll mills is a crucial part tool in various industries. It has been used since the early 19th century for grinding, dispersing, and mixing materials in roller mill, triple roll mill, rolling mill, and high energy ball mill equipment. This rolling mill features three horizontally positioned rolls that rotate at different speeds as part of its design. The unique design, featuring a centre roll and a roll gap, allows for effective processing of viscous materials like inks, paints, and cosmetics using high-performance ceramics as part of the system.

Manufacturers rely on three roll mills to achieve uniform particle size and consistent texture. This equipment enhances product quality by ensuring proper dispersion of pigments and fillers, including color masterbatch as input material and roll materials as part, to optimize performance for dispersions. Understanding what a three roll mill is used for can help businesses optimize their production processes. It’s not just about mixing roll materials; it’s about creating high-quality products that meet customer demands.

Key Takeaways

- Three roll mills are essential for creating uniform mixtures in various industries, including cosmetics, food, and pharmaceuticals.

- To effectively use a three roll mill, ensure proper setup and maintenance to achieve optimal performance and product quality.

- Consider the specific benefits of three roll mills, such as improved particle size reduction and enhanced product consistency, when selecting equipment for your manufacturing needs.

- Different types of three roll mills are available; choose one based on your production volume and the materials you work with.

- Explore the diverse applications of three roll mills to identify how they can improve your production processes and meet industry standards.

- Review case studies to learn from real-world examples of how three roll mills have successfully enhanced efficiency in manufacturing settings.

Understanding Three Roll Mills

Definition

Three roll mills are specialized equipment used for processing viscous materials. They often handle products like inks, paints, and cosmetics. These speed mixers excel at mixing and refining semi-solids and viscous small-batch products to achieve the desired consistency with a 50-mm diameter three-roll mill.

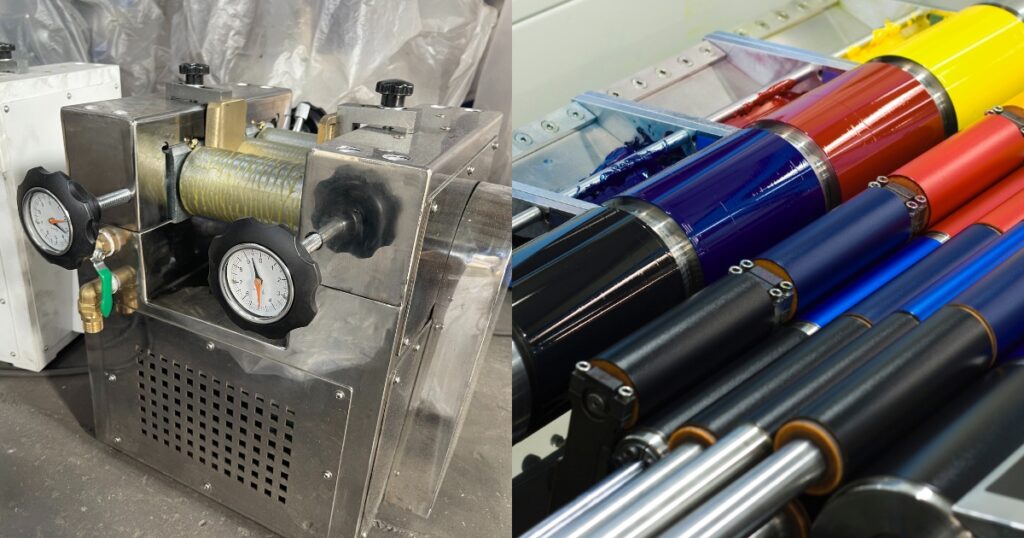

Key Components

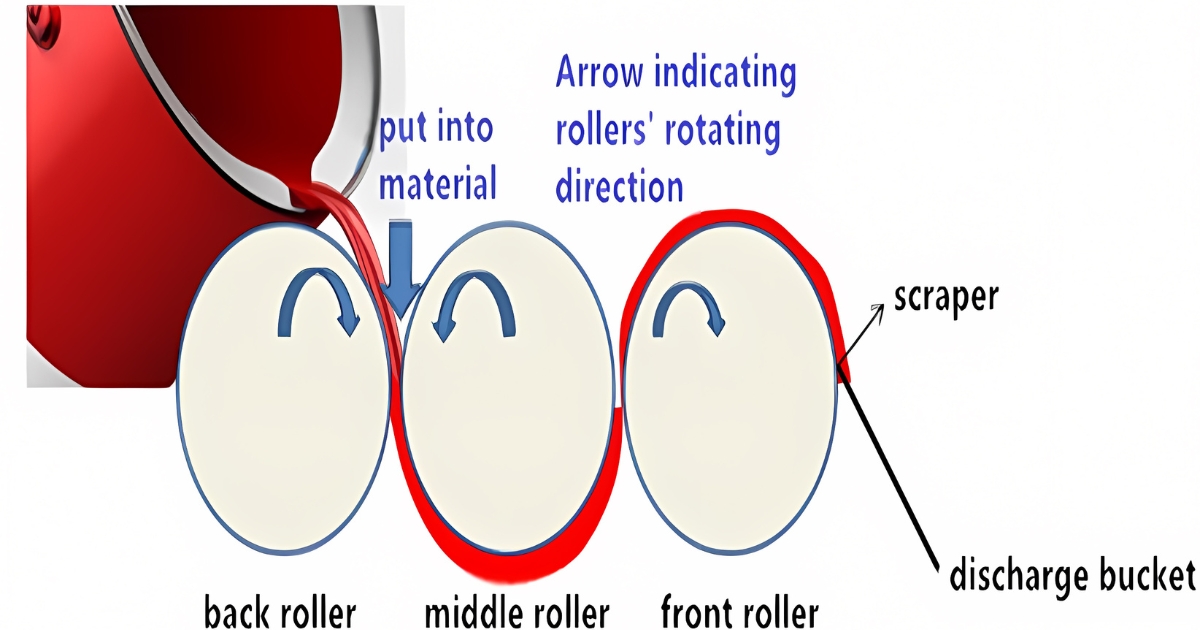

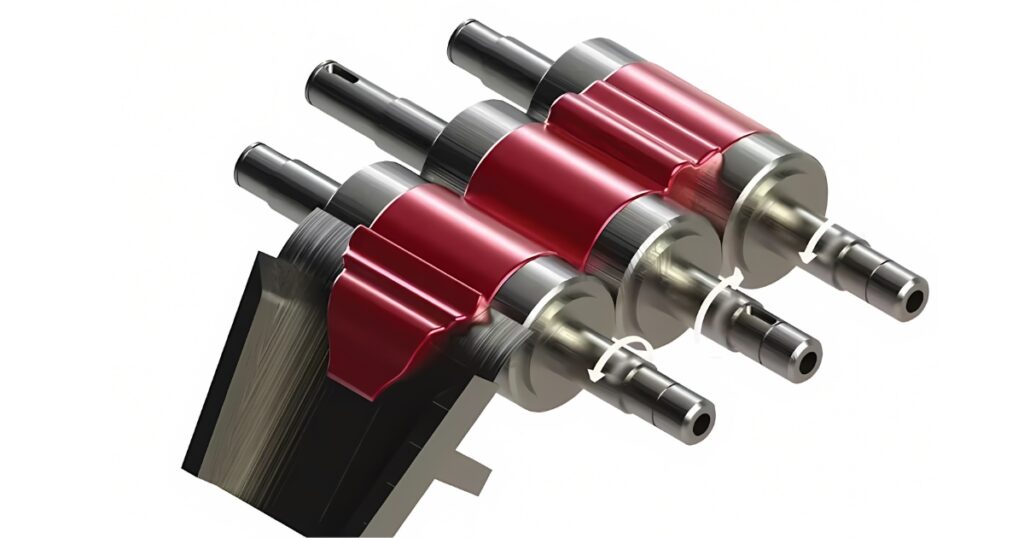

The main parts of a three roll mill include three rolls arranged in a horizontal line. Each roll has a different diameter. The outer rolls rotate in opposite directions at a specific rotation speed while the center roll remains stationary, resulting in a different circumferential speed. This setup creates a unique milling cycle that enhances the mixing process to roll materials.

The rolls are typically made from hardened steel to withstand wear and tear. Abrasion-resistant materials and corrosive materials play a vital role because their durability is crucial as they operate under high pressure and speed. The precise arrangement of the rolls allows for effective shear force application during processing.

Shear Force Significance

Shear force plays a vital role in the operation of three roll mills. It occurs when shear forces cause layers of material to roll materials and move at different speeds and at varying shear rates and shear levels. This movement rolls materials, breaks down particles, and ensures uniform distribution throughout the mixture.

In applications like ink production, shear force acts as a dispersion tool to help disperse pigments evenly in roll materials, improving dispersion quality in film inks and addressing the cohesion of carbon black. This results in a smooth texture and vibrant color. In cosmetic manufacturing, it aids in achieving a fine emulsion with roll materials, which is essential for product quality.

The effectiveness of shear forces can be adjusted by changing the gap between the rolls. A smaller gap increases pressure and enhances mixing efficiency. Conversely, a larger gap reduces pressure but may not mix roll materials as thoroughly, leading to additional shear forces and potential loss of volatiles, affecting dispersion in pastes.

Applications

Three roll mills find use across various industries. They are common in paint production, where they roll materials to create smooth finishes. In the food industry, they help produce chocolate and other confections with consistent texture using roll materials and cocoa powder.

Pharmaceutical companies also utilize these machines to roll materials and ensure proper blending of active ingredients. The ability to control particle size in a class of carbon nanoparticles and roll materials is crucial for drug effectiveness.

Operation Process

The operation of a three roll mill involves several steps in the grinding process, milling cycle, cold rolling processes, and manufacturing process.

- Feeding: Material enters through the feed roll.

- Mixing: Adjacent rolls work together to mix materials.

- Refining: The final product passes through the center rolls for refinement.

- Discharge: Finished material exits from the end of the mill.

This process ensures quality control and control during processing, so materials undergo thorough mixing and refining before becoming the finished product in cold working processes.

How Three Roll Mills Work

Roll Mill Mechanics

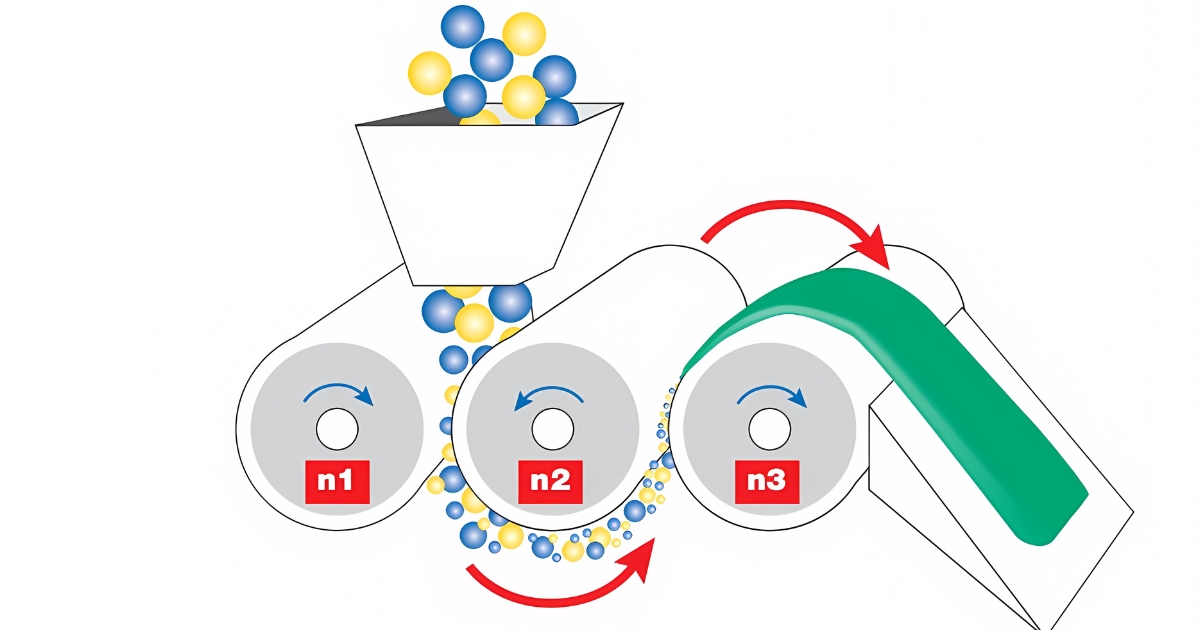

Three roll mills operate through the rotation of three cylindrical rolls. Each roll spins at a different speed. The first roll, known as the feed roll, moves the material into the mill. The second roll, called the middle roll, has a higher rotation speed and circumferential speed than the feed roll among the center rolls. This difference in speed creates a shear force that helps break down and disperse materials effectively.

The third roll, or apron roll, turns slower than the middle roll. This setup generates a specific shear force that enhances the mixing and grinding of materials. As materials, including semi-solids and crystalline substances, pass between these rolls, they undergo intense pressure and shear, leading to a uniform dispersion and equilibrium particle size distribution in the particle dispersions.

Material Feeding Process

Feeding material into the three roll mill is crucial for its function. Operators introduce materials onto the surface of the first roll. Gravity assists in this process, allowing shear forces and materials to flow smoothly into the space between the rolls.

As materials enter, they experience a combination of pressure and shear. This dispersion tool action rolls materials, breaks apart clumps, and evenly distributes particles within the mixture. The design of three roll mills ensures that even viscous materials can be processed efficiently.

Role of Shear Force

Shear force plays a vital role in how three roll mills function. It helps to break down larger roll materials into smaller ones during processing. As materials pass through each gap between the rolls, they are subjected to extreme shear input forces that promote better mixing.

This shear force is essential for achieving desired particle sizes and uniformity in products, especially with viscous materials. For example, paints and inks, as well as roll materials, require fine dispersion for optimal performance. Without sufficient shear force, these materials would remain uneven and ineffective.

Function of Knife Blade

A knife blade is an important component of three roll mills. After the material has been processed by the rolls, it needs to be removed efficiently. The knife blade sweeps across the shear level surface of the last roll to collect finished product.

This action ensures that no material remains on the rolls after processing during the cleaning cycle. It also allows for continuous operation without interruption. Proper use of the knife blade contributes to maintaining clean rolls and high-quality output.

Benefits of Using Three Roll Mills

High Viscosity Handling

Three roll mills excel in processing high-viscosity materials. These materials often require special attention during milling. The design of the three roll mill allows it to exert significant pressure on the material being processed. This pressure helps break down particles effectively, ensuring a uniform product.

For example, industries like cosmetics and pharmaceuticals often deal with viscous materials such as thick pastes or creams. A three roll mill can handle these substances with ease. It ensures that the final product has a smooth texture and consistent quality.

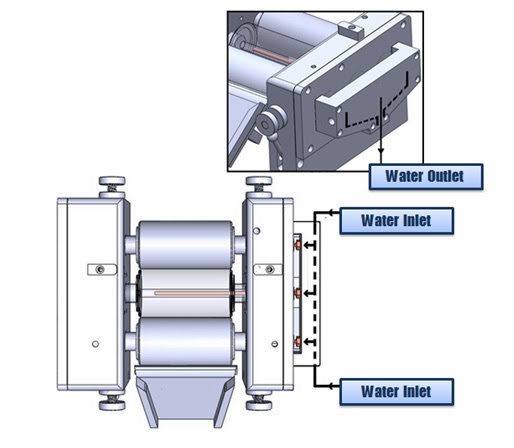

Temperature Control

Temperature management is crucial when milling materials. Three roll mills feature a 1- Cooling system with water-cooled rollers which help maintain an optimal temperature during cold rolling processes using advanced cooling. This cooling system prevents overheating, which can degrade sensitive ingredients.

When the rollers remain cool, the material does not lose its properties. For instance, heat-sensitive compounds in inks or coatings, including chemical materials and corrosive substances, benefit from this feature. The ability to control temperature leads to improved performance and longevity of the final product.

Repeatability of Results

Consistency is key in manufacturing. Three roll mills provide repeatability in the milling process. Each pass through the rollers yields similar results, which is essential for quality control.

Manufacturers can rely on this consistency for batch production. They can easily reproduce formulations without significant variations. This reliability, through quality control and safety standards, enhances customer satisfaction as clients receive uniform products every time.

Versatile Applications

The versatility of three roll mills makes them suitable for various industries. They are commonly used in paint, ink, and adhesive production. Their ability to process different types of ferrous metals and materials makes them valuable tools, playing a vital role.

Businesses can adapt their use based on specific needs. For example, a company might switch from producing inks to coatings through material transfers without needing new equipment. This adaptability saves time and resources.

Efficient Production

Efficiency is another major benefit of using three roll mills. The design allows for continuous processing, reducing downtime between batches. Operators can quickly load and unload materials, streamlining the workflow.

This efficiency translates into higher productivity rates for manufacturers. Companies can meet demand more effectively while maintaining high standards of quality.

Cost-Effective Solution

Investing in a three roll mill can be cost-effective in the long run. While initial costs may seem high, the durability and efficiency of these machines lead to lower operational costs over time.

Reduced waste and consistent results mean fewer resources spent on rework or adjustments. As businesses grow, the return on investment becomes clear.

Types of Three Roll Mills

Hydraulic Roll Mill Types

Hydraulic three roll mills are popular in various industries. They use hydraulic pressure to control the roller spacing and the gap between the rolls. This feature allows for precise adjustments and consistent results. The hydraulic system enhances efficiency and reduces operator fatigue.

These mills often come in different sizes. Smaller models fit well in labs for low-volume production, while larger ones, like the full-sized mill, serve industrial applications with adjustable gap size for the largest pieces. Each type has its strengths, based on the required output and material properties.

Lab Type Roll Mills

Lab type roll mills with ceramic balls are designed for research and development. These mills handle small batches of materials. They allow scientists and engineers to experiment with formulations. Users can test new products before scaling up for mass production.

Lab mills often feature adjustable roll speeds and temperatures. This flexibility helps in understanding how crystalline substances behave under different conditions with additional shear forces. Researchers can refine their processes effectively using these mills.

Manual vs Automated Models

Three roll mills can be manual or automated. Manual models require operators to adjust settings by hand. These machines offer simplicity with minimal maintenance but demand more attention during operation, especially when using a manual scrapper.

Automated models include digital controls. Operators can set parameters easily, leading to greater consistency in production. Automation reduces human error and increases safety, especially in high-volume environments, compared to a manual scrapper.

The choice between manual and automated, including 2- hydraulic control, depends on the specific needs of a business. Smaller companies might prefer manual models due to lower costs. Larger manufacturers often opt for automated versions for efficiency.

Laboratory vs Industrial Scale

Laboratory-scale three roll mills focus on small quantities. They support product development and testing phases. These mills help companies innovate without committing to large-scale production.

Industrial-scale mills handle high volumes of materials. They are built for durability and sustained use. Their design ensures that they can process large batches quickly, reducing material processing time with a roll mill machine.

Both types have unique advantages. Lab mills provide flexibility and control during development. Industrial mills offer speed and efficiency for mass production.

Applications in Manufacturing

Industries Served

Three roll mills, a type of grinder, find use in numerous grinding applications across various industries. The cosmetics industry uses these machines to create smooth creams and lotions. They ensure a fine texture by milling the ingredients together effectively.

Pharmaceuticals also benefit from three roll mills. These cylindrical devices help produce viscous small-batch products like ointments and gels with precise consistency. The shear force applied during the grinding process ensures that active ingredients are evenly distributed.

Products Produced

Specific products made using three roll mills include inks and coatings. Inks require a uniform particle size for consistent color and performance, ensuring quality dispersion and optimal dispersion quality of colored carbon black while maintaining the cohesion of carbon black. Three roll mills achieve this by applying high shear forces, breaking down particles into smaller sizes.

Coatings also rely on three roll mills for quality. Paints and varnishes need to be smooth and free of lumps. The milling process ensures a homogenous mixture of milled material, enhancing the final product’s appearance and durability while considering material processing time.

Emerging Applications

New applications for three roll mills continue to emerge, especially in electronics, advanced materials, production of graphene, non-ferrous products, and alloy steel. Manufacturers use these machines to produce conductive pastes for printed circuit boards (PCBs). The precision in milling allows for better electrical conductivity and performance.

Additive manufacturing is another area where three roll mills are gaining traction. These machines help mix materials used in 3D printing processes. By ensuring a uniform blend, they improve the color display and quality of printed objects.

Machine Models

Various models of three roll mills exist to cater to different needs. Some are designed for bench-top use, making them suitable for small-scale production or laboratory settings. Others are larger, suited for industrial applications requiring high throughput, including bench types, lab type, largest pieces, and gap size.

Cold rolling processes also utilize three roll mills. These machines can shape materials using cold working processes without heating them, maintaining their structural integrity, similar to the cold casting method used for glass ceramics. This method is efficient for producing thin sheets of metal or plastic.

Improving Production Efficiency

Optimize Milling Techniques

Production efficiency in a three roll mill can be enhanced through specific techniques. Adjusting the gap distance between the rolls is critical. A smaller gap often leads to better dispersion but may slow down feed volume. Operators should experiment with different gap settings, including knife edge adjustments, for optimal gear quality results.

Controlling the speed of each roll also plays an important role. Setting the rolls to rotate at different speeds creates mechanical stirring. This action helps in breaking down particles more effectively. For instance, if the front roll spins faster than the back roll, it generates shear force that improves mixing.

Regularly monitoring the feed rate is essential. An appropriate feed ensures that materials pass through the mill efficiently. Too much paste-like materials can cause clogging, while too little careful energy input can lead to inefficient processing and loss of volatiles.

Regular Maintenance

Consistent performance of a three roll mill requires regular maintenance. Checking the alignment of the rolls is vital. Misalignment can lead to uneven wear and reduced efficiency. Operators should routinely inspect and adjust the alignment with a precise adjustment of the adjustable gap size as needed using an adjustment device.

Cleaning the rolls is another important task. Residue buildup can hinder production and affect product quality. Scheduled cleaning prevents contamination and maintains optimal performance.

Lubrication of moving parts is necessary as well. Proper lubrication reduces friction and wear on components. It also ensures smooth operation, which contributes to overall efficiency, making it a perfect solution for 2-hydraulic control.

Advanced Control Systems

Incorporating advanced controls can significantly improve milling processes. These systems allow for real-time monitoring of various parameters like speed, gap distance, and feed rate. By using sensors, operators can track changes instantly.

Adjusting parameters on-the-fly enhances production flexibility. For example, if dispersion levels are low, increasing the speed or adjusting the gap can quickly remedy the situation. This adaptability leads to better product consistency.

Data collected from these advanced systems aids in decision-making too. Analyzing trends helps identify areas for improvement over time. Operators can make informed adjustments that enhance overall output.

Case Studies in Industry

Paint Manufacturing

Three roll mills play a crucial role in the paint industry. Companies use them to achieve uniform dispersion of pigments. For example, a major paint manufacturer enhanced its product quality by integrating three roll mills into its production line. The process allowed for finer particle sizes of colored carbon black and black powder, resulting in vibrant colors and improved texture. This led to higher customer satisfaction and increased sales.

The time taken to produce each batch decreased significantly. By using three roll mills for particle size reductions, the company reduced its production timelines by 20%. This efficiency gain allowed them to meet growing market demands quickly.

Cosmetics Production

In the cosmetics sector, three roll mills are vital for creating smooth creams and lotions. A well-known skincare brand incorporated three roll mills to refine its formulations. The result was a better blend of smooth ingredients, leading to products that felt luxurious on the skin.

This integration also sped up production times. The brand reported a 30% reduction in the time needed for product development. Faster turnaround times helped them launch new products more frequently.

Food Industry

The food industry benefits from three roll mills as well. Chocolate manufacturers utilize these machines to create silky chocolate textures. One chocolate company improved its product quality by adopting a three roll mill system with Torrey Mills made of chrome steel. The machine ensured even mixing of cocoa solids, sugar, and fats.

As a result, the company noticed an improvement in product quality and flavor consistency across batches, including speck-free pastes. Production timelines also shrank by 25%. This change allowed them to respond quickly to seasonal demand peaks.

Adhesives and Sealants

In the adhesives and sealants market, three roll mills contribute to better bonding properties in dental composites. A leading adhesive manufacturer implemented this technology to enhance their product formulations. The machine provided superior mixing and dispersion of raw materials.

This upgrade not only improved product performance with chrome steel but also cut down on production time by 15%. The manufacturer could meet client deadlines more effectively, strengthening customer relationships.

Insights from Successful Companies

Several companies have shared their success stories after integrating three roll mills into their operations. These businesses highlight improvements in both product quality and production speed. They emphasize the importance of investing in essential tools and high-quality machinery.

In interviews, executives noted that three roll mills allowed for greater control over the manufacturing process. They appreciated how these machines minimized waste, maximized efficiency, and reduced energy consumption.

By adopting this technology for suitable applications, companies can enhance their competitive edge in various markets.

Comparing Three Roll Mill Models

Capacity Criteria

Capacity is a key factor when evaluating three roll mill models. Higher capacity mills can process larger batches of materials. This is essential for industries needing significant output, such as paints and coatings, and suitable applications in the production of specialty inks, chemical production, and raw material.

Different models offer various capacities. Some may handle 5 liters per hour, while others can exceed 100 liters. Businesses must assess their production needs carefully. Selecting a model, whether bench models or floor models, that aligns with these needs ensures the perfect solution and efficiency.

Speed Specifications

Speed also plays an important role in performance. Faster mills reduce processing time, increasing productivity. Most three roll mills have adjustable speeds to accommodate different materials.

For example, some models operate at speeds of 0 to 300 RPM with different motor types, gear ratios, and center roll moves. Others might go up to 600 RPM for specific applications. Understanding the speed requirements for your material can help in making an informed choice.

Popular Brands Comparison

Several brands dominate the three roll mill market. Each brand offers distinct features and specifications.

- Exakt: Known for precision and reliability, Exakt mills are popular in laboratories.

- Torrey Hills Technologies: Offers cost-effective models with good performance.

- Bühler: Provides high-capacity options suitable for industrial applications.

These brands often include digital controls, safety features, easy maintenance options, and cable covers. Evaluating these aspects helps businesses choose the right model.

Cost-Effectiveness

Cost-effectiveness is vital for any investment in equipment. Companies should weigh the initial cost against expected returns. A more expensive model, such as floor models, may offer better durability and efficiency, leading to lower operational costs over time and reduced energy consumption.

Consideration of maintenance costs is also crucial. Some models require more frequent servicing, which can add up despite minimal maintenance. A less costly model might seem appealing but could lead to higher long-term expenses.

Return on Investment

Return on investment (ROI) varies by model and application. An efficient three roll mill can significantly enhance production quality and speed. This improvement translates into higher sales and customer satisfaction.

Businesses should calculate potential ROI based on their production goals. They can look at metrics like increased output or reduced waste material. Analyzing these factors helps in determining which bench models provide the best financial benefits.

Final Remarks

Three roll mills are essential tools in many manufacturing processes. They enhance product quality, improve efficiency, and offer versatility across a wide range of various industries. Understanding how these machines work and their benefits can significantly impact your operations. You’ve seen how different models cater to specific needs, making it easier for you to choose the right one.

Now is the time to consider integrating a three roll mill into your production line. Whether you’re looking to boost efficiency or improve product consistency, these machines can deliver. Explore your options from a wide range, and don’t hesitate to reach out for expert advice tailored to your broad range of unique requirements. Your success in manufacturing starts with the right equipment.

Frequently Asked Questions

What is a three roll mill?

A three roll mill is a machine used to refine materials by passing them through three horizontal rollers. It ensures fine dispersions and reduces particle size, commonly used in industries like inks, paints, and cosmetics for grinding and mixing materials effectively.

What industries use three roll mills?

Three roll mills are used in industries such as paints, inks, cosmetics, pharmaceuticals, and food processing. They provide precise particle size reduction and mixing, ensuring uniform consistency in products like ointments, pastes, and emulsions.

How do three roll mills work?

Three roll mills work by feeding material through three rotating, horizontally aligned rollers. The rollers apply pressure and shear forces as the material passes between them, breaking down particles and achieving fine dispersion. This process is commonly used for mixing and grinding in industries like paints, inks, and cosmetics.

What are the benefits of using a three roll mill, including vertical roller mills, rolls mills, and the cold rolling process?

The benefits of using a three roll mill, vertical roller mills, and the cold rolling process include precise particle size reduction, improved material dispersion, and uniform consistency.

These methods enhance product quality by minimizing clumping and ensuring smooth textures, making them ideal for industries like cosmetics, inks, and metals.

Are there different types of three roll mills?

Yes, there are several types of three roll mills, including manual, motorized, and digital models. Each type of articles in types caters to specific needs based on production scale and precision requirements.

Can three roll mills improve production efficiency?

Yes, three roll mills streamline the mixing process, reduce processing time, and enhance product consistency. This leads to higher output and improved operational efficiency.