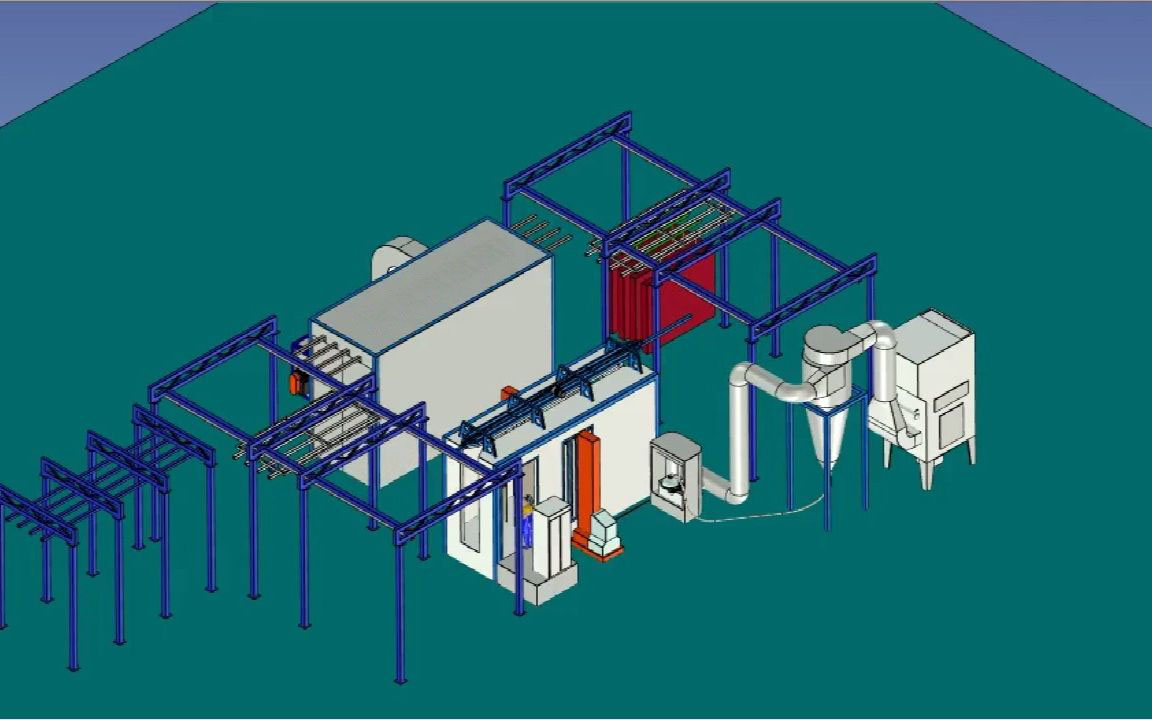

OEM coating equipment production lines, including extruders and paint mixing systems, are crucial in various manufacturing sectors. These lines enhance efficiency, ensure high-quality finishes, and highlight the advantages of powder coating, such as superior color retention and leveling properties. Designed for specific production needs, they provide flexibility, precision, and easy automation. Advanced technology, like electrostatic powder coating machines, is integrated to optimize performance and reduce waste.

Choosing the right equipment, such as a powder coating line or electrostatic powder coating machine, impacts productivity, costs, and quality. Understanding the components and processes is essential for manufacturers to achieve optimal results. This post explores the key features of OEM coating production lines and offers best practices for their implementation and maintenance.

Key Takeaways

- OEM coating equipment is essential for manufacturers looking to improve product quality and consistency in their production lines.

- Enhancing production efficiency can be achieved by investing in advanced coating technologies that reduce waste and increase throughput.

- When selecting equipment, consider factors like production volume, specific coating requirements, and industry standards to ensure the best fit for your needs.

- Different industries have unique coating challenges; tailor your approach by researching industry-specific considerations and best practices.

- Review case studies of successful implementations of a powder coating line to gain insights into effective strategies and potential pitfalls in adopting new equipment.

- Consulting with coating experts can provide valuable guidance on optimizing your production line and selecting the right equipment for your business.

Understanding OEM Coating Equipment

Definition

OEM coating equipment, including tunnel oven, refers to Original Equipment Manufacturer tools used in the coating industry. This equipment plays a crucial role in the powder coating industry. It helps apply protective and decorative finishes on various surfaces using a powder coating line and coating process equipment. The equipment ensures high quality and durability of coatings.

Benefits

Using OEM equipment offers several advantages. Consistency is one of the primary benefits. OEM coating equipment maintains uniformity in the application process. This leads to reliable results, reducing defects and rework. High-performance levels are another significant advantage. The right coating process equipment enhances efficiency and productivity.

IPCO’s Contribution

IPCO’s powder coating line equipment converts blended pre-mix into a homogeneous material. This process, including proper surface preparation and optimal drying speed, is essential for achieving ultimate color retention in powder coating production processes. The machinery ensures that all components mix thoroughly. This thorough mixing leads to a consistent application.

Types of Equipment

Various types of OEM coating equipment, including painting machines and pharmaceutical sterilizers, exist in the product range of the market. These include:

- Powder coating machinery

- Dip coating process equipment

- Manual powder coating systems

Each type serves specific functions in the production line.

Manufacturers

Numerous companies specialize in manufacturing coating process equipment. They offer a range of product lines and solutions tailored to different clients’ requirements based on Business Type, including coating process equipment, in their product portfolio. Some may focus on high temperature OEM coating technology while others specialize in enamel or powder coatings. Researching reputable coating process equipment manufacturers is vital for selecting appropriate tools.

Production Lines

The setup of an automatic powder coating line is critical for large-scale operations. These lines streamline production, ensuring faster output of batches of products with minimal labor costs using coating process equipment. They also integrate advanced features for better control over the powder coating line application process.

Quality Assurance

Quality assurance is paramount in the coating process. Using highland high temp OEM coatings with superior corrosion resistance and outstanding corrosion protection can enhance performance under extreme conditions while providing a durable finish. These coatings withstand high temperatures without degrading, ensuring longevity.

Innovation

Innovation drives advancements in the powder coating manufacturing field. New technologies emerge regularly, improving efficiency and effectiveness. Companies must stay updated on trends to remain competitive.

Summary

In summary, understanding OEM coating equipment is essential for success in the powder coating industry. Its role in ensuring quality and consistency in the coating process equipment, alongside outstanding performance within the standard range, cannot be overstated. By choosing appropriate equipment and manufacturers, businesses can enhance their production capabilities significantly.

Importance for Manufacturers

Reliable Equipment

Reliable coating equipment is crucial for manufacturers. It ensures that production demands are met consistently. High-quality coatings protect products and enhance their appearance. Manufacturers rely on this equipment to maintain output levels. Any failure in the coating process, including dry times, can lead to delays and increased costs.

Investing in dependable OEM coating equipment reduces these risks. Manufacturers can avoid interruptions in their production lines. This reliability leads to better planning and scheduling. With consistent performance, manufacturers can meet customer expectations effectively.

Enhanced Product Quality

OEM coating equipment significantly enhances product quality. It allows for precise application of coatings. This precision leads to a uniform finish on products. Consistent quality helps build brand reputation.

Reducing waste is another advantage of using OEM equipment. Advanced technology minimizes overspray and material loss during the coating process, ensuring precise coatings and a high-quality finish with Quick-Dry Coatings and wet paint coatings. This efficiency lowers production costs and improves profit margins. For example, a manufacturer using efficient equipment may see a 20% reduction in material waste over time.

Competitive Advantage

Advanced technology plays a key role in gaining a competitive edge in manufacturing, particularly for Coating Process Equipment Manufacturers in the automotive industry. OEM coating equipment often incorporates the latest innovations. These technologies improve speed and accuracy in the coating process.

Manufacturers using cutting-edge equipment and advanced technology can respond quickly to market changes. They can adapt their coating process equipment and production lines to meet new demands swiftly. This flexibility is vital in today’s fast-paced environment.

Investing in advanced OEM technology, including coating process equipment, can also attract new customers. Companies that prioritize quality and efficiency in their coating process equipment Company Introduction stand out against competitor products in crowded markets. By showcasing superior products, manufacturers can gain trust and loyalty from consumers.

Cost Efficiency

Cost efficiency is another significant benefit of reliable OEM coating equipment, which provides excellent color stability and long-lasting color stability. Lower operational costs lead to higher profitability for manufacturers. Efficient machines require less maintenance and reduce downtime.

Moreover, manufacturers can produce more goods with fewer resources and lower production costs when using high-quality equipment. This increased productivity in coating process equipment translates into better financial performance over time.

Sustainable Practices

Sustainability is becoming essential in manufacturing practices today. OEM coating equipment often features eco-friendly options, such as solvent venting ovens, that reduce environmental impact. Manufacturers adopting these practices appeal to environmentally conscious consumers.

By reducing emissions and waste, companies contribute positively to society and demonstrate environmental friendliness while maintaining profitability.

Enhancing Production Efficiency

High-Throughput Solutions

IPCO’s high-throughput coating process equipment solutions play a crucial role in enhancing production efficiency. These systems utilize advanced technology to optimize the manufacturing process and enhance production processes, including production lines, Coating Machines, and powder coating machinery. The integration of an efficient extruder is vital. It ensures a consistent flow of materials through the coating process equipment, which minimizes delays.

Incorporating a PCC (Process Control Center) can further boost production. This center monitors and adjusts parameters in real-time. It helps maintain optimal conditions throughout the production line. As a result, manufacturers can achieve faster production times and higher output rates using coating process equipment without compromising quality or affecting production throughput.

Regular Maintenance

Regular maintenance schedules are essential for preventing downtime. Scheduled inspections keep equipment running smoothly. For instance, checking the steel belt cooler and the coating process equipment ensures it operates at peak performance. This cooler is critical for controlling temperatures during production.

Maintenance should include monitoring barrel lengths as well. Variations in barrel length and coating process equipment can affect product quality and consistency. By adhering to a strict maintenance routine for coating process equipment, manufacturers can ensure continuous production and avoid costly interruptions during the warranty period.

Automation Options

Automation options present significant opportunities to streamline processes. Automated systems reduce the need for manual intervention. This leads to faster production times and less human error in the coating process equipment.

Implementing robotic systems can enhance efficiency on the production line. Robots can handle repetitive tasks quickly and accurately. They also free up human workers for more complex duties.

Manufacturers can also explore software solutions that facilitate automation. These programs help manage inventory and track production metrics in real-time. Improved data analysis allows for quick decision-making, optimizing overall output.

Selecting the Right Equipment

Assessing Needs

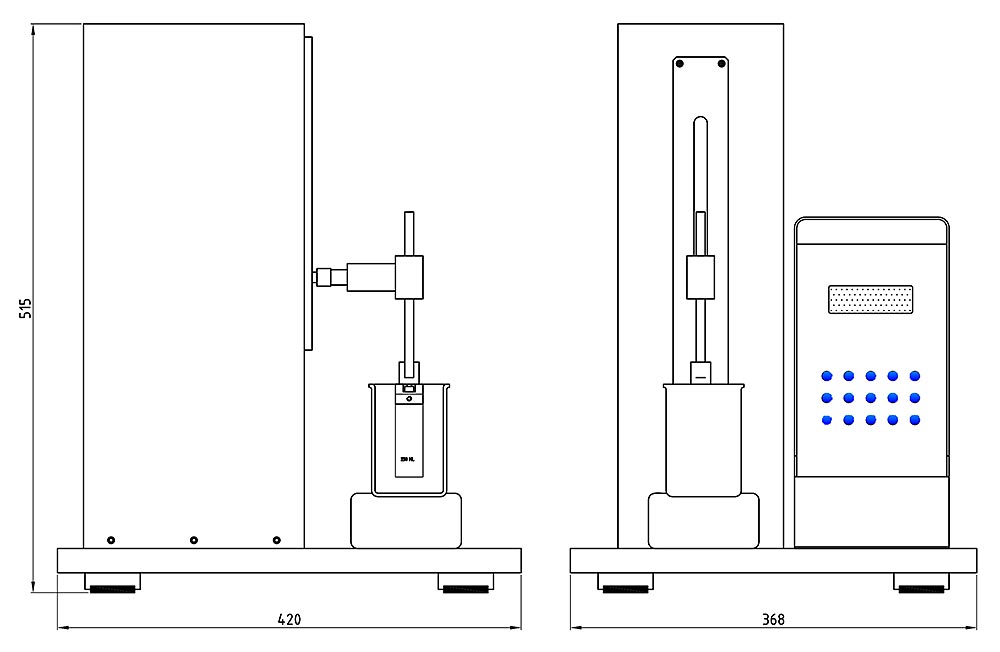

Manufacturers must first assess their specific needs. Understanding production goals is essential. This includes knowing the desired output, the types of products to be coated, and the coating machines used in specialized coating systems for a successful powder coating operation and coating equipment production lines. Evaluating the screw diameter is crucial as it impacts the material flow and quality. A larger screw diameter can handle higher throughput, while a smaller one may be better for precision.

The production line’s layout also affects equipment choice. Space constraints may limit options. Manufacturers should consider how much room they have for machinery. They need to think about future expansion too. Choosing equipment that can adapt to a range of options and changing demands is wise.

Comparing Options

Different extruder options are available in the market. Each has unique features that cater to a wide range of throughput requirements and barrier properties, providing a range of options for different Method Types. For instance, some extruders work well for high-volume production, while others are better suited for smaller batches.

Manufacturers should compare these options based on their operations. They must look into factors like energy consumption, operational costs, and maintenance needs for the dormitory building. Some machines offer better efficiency and lower operational costs over time. Analyzing these aspects helps in making informed decisions.

Customizing Setups

Utilizing IPCO’s 3D configurator can enhance the selection process. This tool allows manufacturers to visualize different equipment setups. It enables users to see how various components fit together with design capabilities before making a purchase.

Customization options include adjusting the cooler placements and other features. This flexibility helps ensure that the line meets specific production needs. By visualizing setups, manufacturers can avoid costly mistakes later on.

Making Informed Decisions

Informed decisions lead to better outcomes in production efficiency. Manufacturers should gather data from their current operations. They can use this information to identify gaps or areas needing improvement.

Consulting with experts can also provide valuable insights. Industry professionals often have experience with various equipment types and configurations within the standard range. Their knowledge can guide manufacturers in selecting the best solutions for their production lines.

Industry-Specific Considerations

Unique Challenges

Different industries face unique challenges when implementing OEM coating equipment production lines. For example, the automotive sector requires high precision. Coating must withstand harsh conditions, meet strict durability standards, and provide industrial grade corrosion resistance like traditional coatings, ensuring a durable finish with LINE-X Protective Coatings. In contrast, the electronics industry prioritizes fine detail and cleanliness. Contaminants can affect performance, so equipment must minimize dust and particles.

The food processing industry has its own challenges. It demands coatings that are safe for food contact. Compliance with health regulations is essential. Equipment must also be easy to clean, with proper surface preparation and a drying room, to avoid contamination. Each industry’s specific requirements dictate how equipment is designed and operated.

Regulatory Standards

Regulatory standards vary across sectors. The medical device industry, including pharmaceutical sterilizers, adheres to stringent guidelines from organizations like the FDA. Coatings used in this field must be biocompatible and safe for human use. Equipment must facilitate thorough testing to ensure compliance.

In the aerospace industry, coatings need to resist extreme conditions. They must endure high temperatures and corrosive environments. Therefore, original equipment manufacturer coating lines must include features that meet these rigorous specifications.

Tailoring equipment features to meet these standards is crucial. Manufacturers often consult with regulatory bodies during the design phase. This ensures that the equipment meets all necessary criteria before production begins.

Energy Efficiency

Energy efficiency plays a significant role in selecting coating equipment. Many businesses prioritize sustainability in their operations. Energy-efficient machines reduce operational costs over time. They also lower carbon footprints, aligning with global sustainability goals and promoting environmental friendliness.

Investing in energy-efficient coating lines can yield long-term savings. Companies may qualify for incentives or rebates by using green technologies. Furthermore, energy-efficient systems often improve overall productivity by reducing downtime.

Sustainable practices extend beyond energy use. Manufacturers increasingly consider the materials used in coatings and processes. Non-toxic materials are favored to promote a safer working environment.

Range of Materials

The range of materials used in OEM coating processes is diverse. Different industries require various types of coatings, such as industrial grade corrosion protection, based on their needs. For instance, automotive applications often use powder coatings for durability and finish quality.

Conversely, industries such as pharmaceuticals may choose liquid coatings for their ease of application. Each material type and coating types have distinct properties that affect performance and suitability for specific applications.

Understanding these material differences is vital when selecting equipment. It ensures that the chosen product lines can handle the desired materials efficiently.

Case Studies of Successful Implementations

IPCO Equipment

IPCO has provided various clients with customized coating solutions. One notable example is a major automotive parts manufacturer. This client faced challenges with their previous coating process. They struggled with long cycle times and inconsistent quality. After implementing IPCO’s coating equipment, the client reported a 30% increase in throughput. This change allowed them to meet rising demand without sacrificing quality.

Another case involves a consumer goods company. The company needed a solution for their packaging line. They required a more efficient way to apply coatings. IPCO developed a tailored system that improved application precision. As a result, the client saw a 25% reduction in operational costs. This significant savings came from less material waste, fewer reworks, and reduced labor costs.

Client Testimonials

Clients have shared positive experiences after using IPCO’s equipment. One manufacturing manager stated, “The new system transformed our production line.” This feedback highlights the impact of customized equipment on operations. Another client emphasized how the equipment improved their product consistency. They noted, “We now deliver durable, high-quality products with outstanding performance every time.” Company Introduction.

Moreover, clients appreciate the support they receive during implementation. IPCO provides training and ongoing assistance to ensure smooth transitions. A food processing client mentioned how helpful this Installation Service support was during their upgrade to meet clients requirements. They said, “The team was there every step of the way.” Such testimonials reflect the value of strong partnerships in achieving success.

Measurable Outcomes

Measurable results are crucial when evaluating equipment performance. Clients often track metrics such as throughput, operational costs, and cost savings. For instance, one electronics manufacturer monitored their output closely after installation. They discovered that they could produce 15% more units per hour compared to their old system.

Many clients report improved employee satisfaction. Operators find the new systems easier to use and maintain. A textile manufacturer shared that employee turnover decreased after upgrading their equipment. Workers in the United Kingdom felt more confident and engaged with the new technology.

Industry Impact

The impact of IPCO’s solutions extends beyond individual clients. Many industries benefit from enhanced efficiency and reduced costs. Automotive, consumer goods, electronics, and Agriculture & Food sectors all see improvements in production lines for a range of products. These advancements lead to better products for consumers.

IPCO’s commitment to innovation drives these successes forward. Continuous development ensures that clients receive state-of-the-art solutions tailored to their needs.

High Throughput and Large Batch Production

Advantages of PCX Extruders

Thoroughly cooled PCX Extruders offer significant benefits for high volume production with the electrostatic powder coating unit and electrostatic powder coating equipment. These extruders maintain consistent temperatures during the process. This consistency leads to improved product quality and reduced defects. Manufacturers can produce a larger quantity of materials without sacrificing quality.

The cooling system in these extruders plays a crucial role. It ensures that the material does not overheat, which can affect its properties. The result is a more efficient production line that meets high demand for batches of products.

Recommended Cooling Options

Cooling options like the Steel Belt Cooler and Drum Cooling enhance performance in production lines. Steel Belt Coolers provide an even cooling surface. They help in maintaining optimal temperatures across the entire width of the material being processed.

Drum Cooling is another effective method. It uses rotating drums to cool down the extruded material efficiently. Both coating methods ensure that the material cools quickly and consistently, which is essential for maintaining quality standards, especially regarding drying speed and dry times.

Screw Diameter Variations

Different screw diameters cater to various production needs. Smaller diameters are ideal for low-volume applications. They allow for precise control over the material flow and mixing.

Larger diameters suit high-volume production lines. They enable faster processing rates and accommodate more material at once. This flexibility allows manufacturers to adjust their processes based on demand.

Impact on Production Lines

Using PCX Extruders with proper cooling systems and varying screw diameters greatly impacts overall productivity and coating speed. A well-designed production line can handle large batches effectively, reducing downtime between runs.

For instance, a company may switch from a smaller diameter to a larger one as demand increases. This shift allows them to meet customer needs without significant delays or additional equipment costs.

In summary, implementing thoroughly cooled PCX Extruders significantly enhances production capabilities. The use of Steel Belt Coolers or Drum Cooling optimizes performance, while varying screw diameters provides the flexibility needed for different production requirements.

Consulting with Coating Experts

Tailored Solutions

Manufacturers should seek expert advice, particularly on Highland High Temperature OEM Exhaust Coatings, when it comes to custom coating solutions. Each production line has unique needs. Understanding these needs helps in selecting the right industrial coatings. Coating experts can provide insights into the best practices for the powder coating process. They can recommend specific powder coating materials that enhance efficiency.

Consulting with professionals ensures that manufacturers choose the right premium solvent coating liquids and techniques. This leads to a perfect metal surface powder coating. It also minimizes waste and maximizes output. Experts can guide companies in optimizing their powder coating line. They assess existing systems and suggest improvements.

Ongoing Support

Collaboration with IPCO is crucial for ongoing support and maintenance of coating equipment. IPCO provides expertise in managing the entire powder coating industry. Their knowledge aids manufacturers in maintaining high-quality standards over time, especially during the warranty period. Regular consultations ensure that production lines run smoothly and efficiently.

Working closely with IPCO allows manufacturers to stay updated on the latest powder painting technology and specialized coating systems, coating technologies, IXS Coatings, and coating equipment production lines. This partnership can lead to innovative solutions that address production challenges. For instance, they may suggest new paint mixing techniques or advanced powder coating thickness measurement tools.

Addressing Challenges

Consulting sessions are valuable for addressing specific production challenges. Manufacturers often face issues such as uneven coating or equipment malfunctions that affect product quality. Experts help identify root causes and propose effective solutions.

These sessions can also foster innovation within the production line building process. By collaborating with professionals, businesses can explore new methods and technologies. They might discover ways to streamline operations or reduce costs.

Participation in workshops or training sessions can enhance staff skills too. Knowledgeable employees lead to better handling of powder painters and equipment in painting production.

Innovation Focus

Focusing on innovation and product portfolio is essential in the competitive powder coating market. Manufacturers must adapt to changing demands and technologies. Consulting with experts provides insights into emerging trends within the powder coating industry.

Experts can introduce businesses to advanced techniques like conversion coating using metal surface treatment equipment. This process improves adhesion and durability of coatings. Staying informed about these innovations keeps companies ahead of competitors.

Regularly engaging with coating specialists ensures continuous improvement in production quality. With expert guidance and OEM Service, manufacturers can achieve greater consistency in their products.

Final Remarks

The exploration of OEM design manufacturer coating equipment production lines reveals their critical role in modern manufacturing. These systems enhance efficiency, ensuring that manufacturers can meet industry-specific demands effectively. Successful case studies demonstrate the tangible benefits of investing in the right equipment, highlighting advancements in throughput and batch production capabilities.

To remain competitive, manufacturers must prioritize the selection of appropriate coating technologies and consult with industry experts. This strategic approach will not only optimize production processes but also lead to sustainable growth. Engaging with professionals in the field can provide valuable insights that drive innovation. Manufacturers are encouraged to assess their current operations and consider integrating advanced OEM coating solutions with premium solvent for improved outcomes.

Frequently Asked Questions

What is OEM coating equipment?

OEM coating equipment, such as tunnel ovens, is specialized machinery for original equipment manufacturers. It applies protective or decorative coatings to products, improving durability and aesthetics.

Why is OEM coating equipment important for manufacturers?

OEM coating equipment is important for manufacturers because it improves product quality, extends lifespan, and gives a competitive edge. It helps meet industry standards and customer expectations while ensuring consistent quality in OEM services.

How can production efficiency be enhanced with OEM coating equipment, commercial extruders, a powder polymerization oven, a paint mixing system, and powder spray operators?

Production efficiency with OEM coating equipment can be enhanced through automation, precise application, and reduced cycle times. These features minimize waste, optimize resources, and increase output rates.

What factors, including commercial extruders, full powder paint, paint mixing, and barrel lengths, should be considered when selecting OEM coating equipment?

When selecting OEM coating equipment, consider production volume, coating type, barrier properties, system compatibility, and maintenance needs. Evaluating these factors ensures the equipment fits specific manufacturing processes.

Are there industry-specific considerations for OEM coating equipment?

Yes, industry-specific considerations for OEM coating equipment include regulatory compliance, material compatibility, and environmental standards. Tailoring equipment to these factors ensures optimal performance.

Can you provide examples of successful implementations of OEM coating equipment, including extruder configurations, paint mixing techniques, and barrel lengths used in their form?

Examples of successful OEM coating equipment implementations include automotive parts manufacturers and electronics companies. In these cases, the equipment improved efficiency and product quality, leading to significant operational enhancements.

When should manufacturers consult with coating experts?

Manufacturers should consult coating experts during the planning phase, equipment selection, or when facing challenges. Expert guidance ensures informed decisions and optimal coating outcomes.