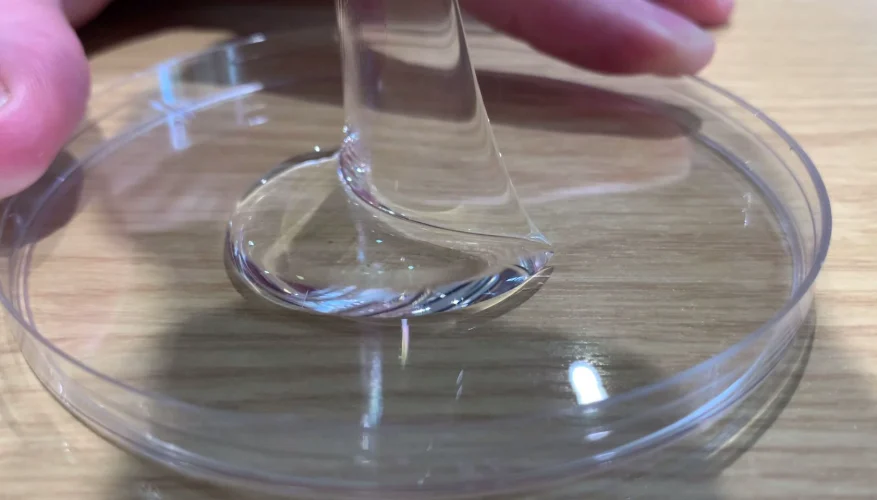

Definition: A Planetary Mixer is a versatile vertical mixing machine designed specifically for handling high-viscosity materials and heavy pastes. Unlike standard mixers, the blades in a planetary mixer rotate on their own axes while simultaneously orbiting a central vessel—similar to the movement of planets around the sun

What Problem Does it Solve? Standard agitators create “dead zones” where thick material sticks to the walls and never gets mixed. The planetary motion ensures the blades cover every point within the vessel, providing a thorough mix for materials that are too thick to flow on their own.

Key Capabilities:

High Viscosity Handling: Effortlessly processes materials up to 3 million centipoise (cPs).

De-aeration: Operates under vacuum to remove air bubbles, essential for high-quality paints and battery slurries.

Temperature Control: Jacketed tanks allow for heating (to melt waxes) or cooling (to prevent degradation) during mixing.