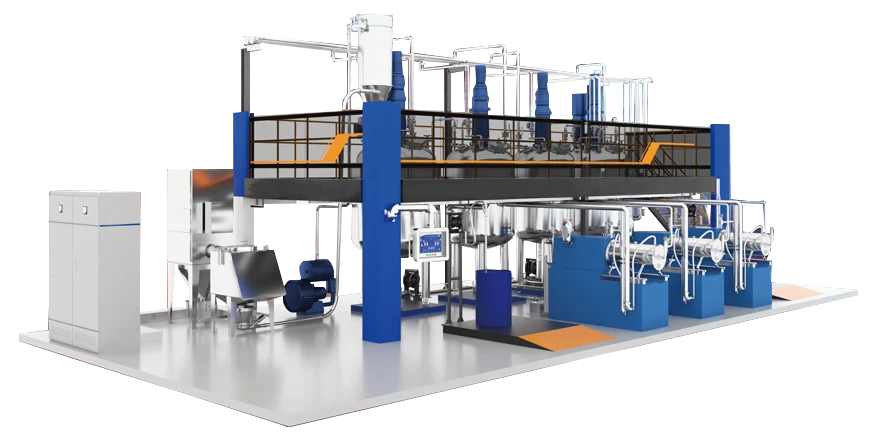

Raw materials Feeding system:

- The raw materials required for the production of the liquid pesticides will be prepared and measured according to the required formula, using a pump to feed the raw material to the mixing kettle.

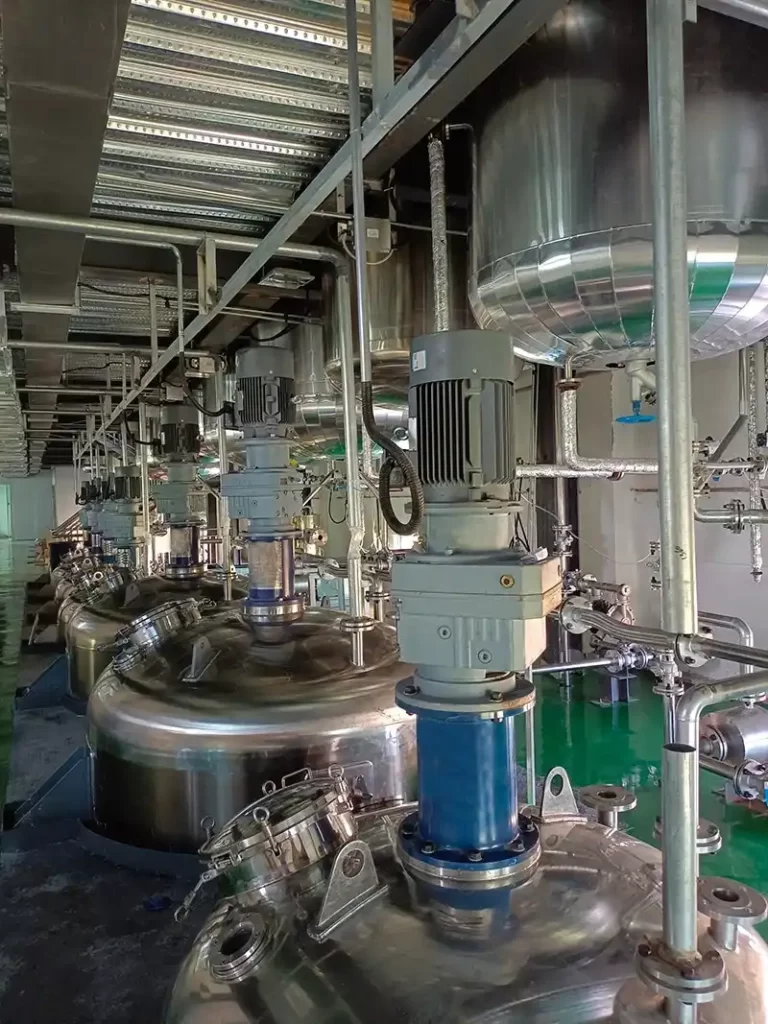

- Mixing kettle: The raw materials will be mixed in the reactor, in a high-shear mixer to create a homogenous mixture.