Enhancing production processes demands equipment that improves both Efficiency is significantly enhanced when using a high-speed dissolver in conjunction with a basket mill. and output Quality assurance is paramount in the selection of materials for use in milling baskets to ensure optimal performance.. Machines designed for diverse industrial applications deliver substantial benefits in various batch production settings.

They offer remarkable efficiency in energy consumption and feature precise control mechanisms, fundamental for achieving exceptional results in product refinement.

By seamlessly integrating grinding and mixing actions, these systems consistently elevate production standards and finish quality.

Their advanced technological elements, such as innovative basket designs, optimize grinding effectiveness and ensure superior quality outputs. This versatility is pivotal across multiple sectors, addressing the distinct requirements of industries like coatings and inks.

Understanding The Grinding Process

Advancements in milling equipment for optimizing production processes have created opportunities for new insights into grinding efficiency. By examining methods to improve particle dispersion, industries like coatings and inks have gained substantial benefits. Basket mills, central to refining the intricacies of particle-size distribution in wet grinding, play a crucial role in maintaining high standards of quality.

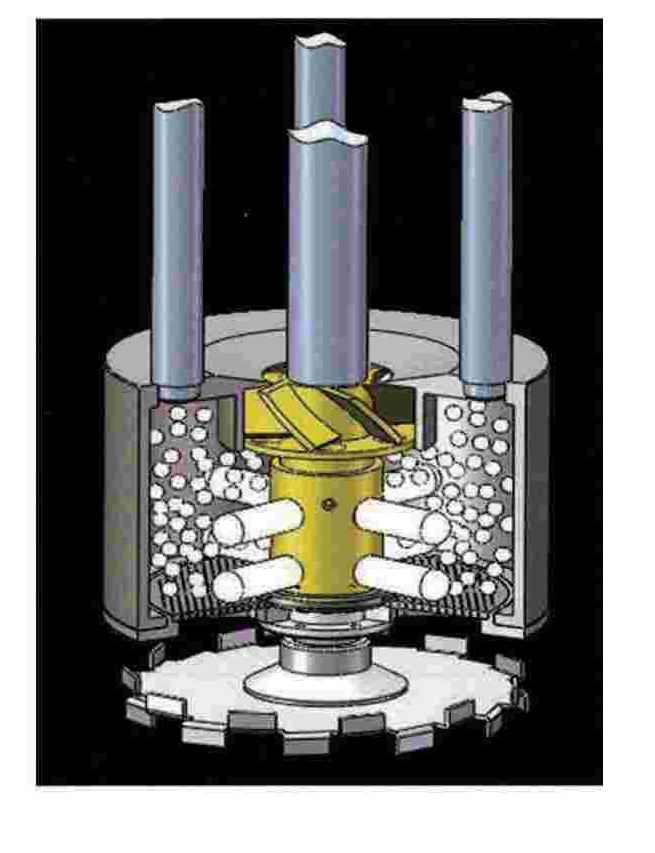

These grinding machines excel by reducing particle size and achieving precise dispersions, down to just a few microns within a sealed system. This feature makes them exceptionally suitable for applications that require high-quality output, such as ink and paint production. Technologies like impellers and innovative basket designs enable excellent control over the grinding and dispersion process.

In the ongoing comparison between basket mills and bead mills, factors such as batch size, viscosity levels, and specific application needs are essential for determining the best grinding equipment. Basket mills, though typically suited for lab and pilot plant environments, offer significant advantages with their ability to manage smaller batches efficiently. They cater to tasks like inkjet printing and various machining processes where precise control is vital.

Furthermore, the adaptability of these machines spans diverse setups, encouraging reduced processing time and enhanced customization potential. By understanding the special requirements of each application, industries can leverage basket mills effectively for optimized performance and efficiency. By achieving a narrow particle size distribution, these systems significantly enhance production capability, bridging the gap between high output and refined quality.

Benefits Of Using Basket Mills in Niche Industries

Utilizing basket mills in niche industries such as paints, inks, and coatings significantly enhances production efficiency through their energy-efficient and excellent grinding capabilities. These advanced systems are pivotal in transforming production processes, aligning with eco-friendly initiatives by reducing energy consumption without compromising on quality.

The energy efficiency of basket mills supports sustainability efforts, allowing industries to meet strict environmental regulations while operating cost-effectively. This is crucial for maintaining competitive advantage in markets increasingly focused on ecological impact. Basket mills provide precise control over particle size, which is essential for achieving uniformity in color and texture, thereby ensuring product stability and quality.

Furthermore, these mills offer operational reliability with minimal maintenance, crucial for consistent production schedules in wet grinding applications. Their design simplifies cleaning, reducing downtime—a key requirement for sectors that rely on uninterrupted production cycles.

By optimizing operational settings, basket mills achieve fine grinding and uniform dispersion of materials like inks, with precise particle size distribution through effective use of mixers and impellers. This delivers superior product quality and efficiency, establishing a new standard for manufacturing excellence in specialized industries.

| Basket Mills | Traditional Mills |

|---|---|

| Energy-efficient | High energy consumption |

| Precise particle size control | Limited particle size control can be addressed by utilizing advanced milling beads in the grinding process. |

| Operational reliability | Requires frequent maintenance |

| The development of eco-friendly milling baskets is becoming a priority for sustainable manufacturing practices. | Less focused on environmental impact |

How To Achieve Fine Grinding

The Role of Basket Systems in Fine Grinding

Exploring the benefits witnessed with basket systems in specialized industries, it’s clear that achieving fine particle sizes enhances product quality and process efficiency. The combination of liquid flow and precise dispersion creates a controlled environment, essential for maintaining a consistent particle size distribution that boosts performance standards.

Innovative Solutions by Industry Leaders

Brands like Torusmill® and Z-mixer series showcase remarkable reliability with their advanced methods. These systems leverage efficient immersion milling to ensure uniformity and precision across various fields. The unique design features a rotating basket, merging high shear forces with accuracy, optimizing the interaction of milling beads—a crucial factor for pigment dispersion and particle consistency, particularly in sectors with stringent performance demands.

Key Influences on Grinding Fineness

Adjusting specific parameters, such as mill speed and bead size in the basket mill, can greatly impact the grinding fineness, demonstrating the tailored approach each industry may require. As practitioners use different milling technologies, moving from traditional bead systems to advanced basket designs, they achieve narrow particle size distributions. The rotating system efficiently disperses and grinds pigments within the mill base. The refinement offered by producers like Torusmill® and ELE provides a compelling option for industries aiming for superior results and operational excellence.

Exploring Milling Technologies

As we look at the details of fine grinding, it is important to study new technologies that increase production efficiency and quality. High-speed mixers, vital in areas such as coatings and inks, boost productivity by ensuring even dispersion and consistent particle-size distribution. With adjustable settings, they offer flexibility across multiple applications. Their energy-efficient design supports sustainable processes, aligning with industry goals.

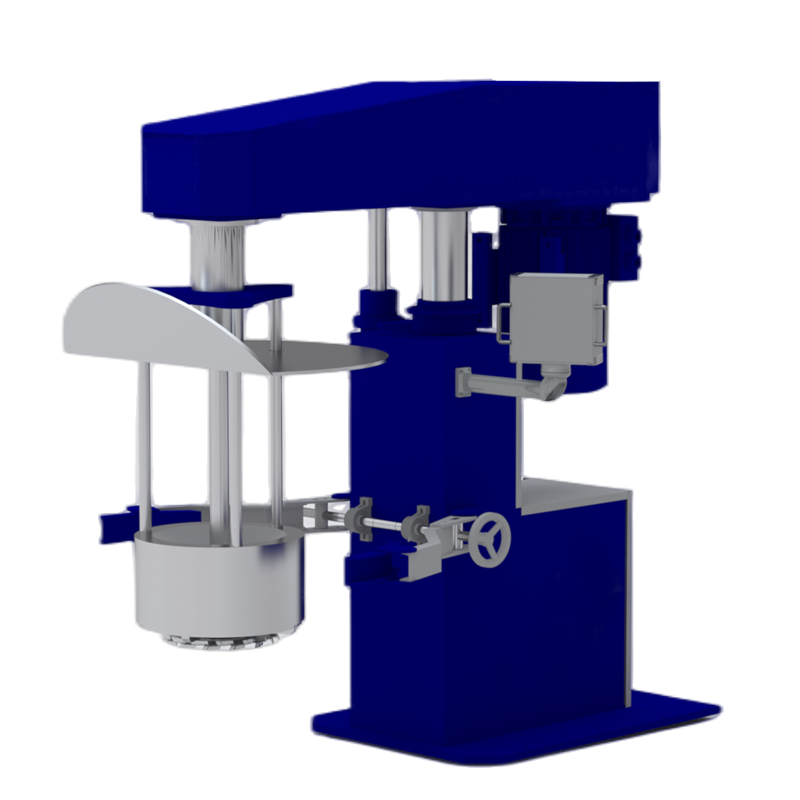

Acrylic emulsion machines have gained importance, tailored for producing quality emulsions through steady shear mixing, achieving a uniform particle size. Similarly, hydraulic lifting high-speed dispersers provide adaptable container handling and ensure thorough pigment dispersal, crucial for consistent product quality.

Disperser machines play a key role in the ink sector, where color consistency directly affects print quality. Additionally, the Z-mixer basket mill design offers a transformative approach, combining grinding and mixing to elevate efficiency and output across the milling industry, particularly when using Z-mixer basket mills.

Examining these technologies reveals the important balance between achieving superior grinding performance and maintaining sustainable practices. As manufacturers embrace these advances in The integration of new technology in the lab basket mill allows for greater precision in milling operations., reaching optimal fine grinding becomes increasingly achievable, keeping industries at the forefront of innovation with the use of advanced grinding mills.

Advanced Manufacturing Solutions

- High-speed mixers boost efficiency and ensure even dispersion crucial for coatings and inks.

- Acrylic emulsion machines utilize steady shear mixing for uniform particle size.

- Hydraulic lifting high-speed dispersers ensure thorough pigment dispersal and adaptable container handling.

- Innovative technologies like the Z-mixer basket mill optimize milling efficiency and output.

The Role Of Impellers In Milling

An in-depth look at high-speed mixers reveals the substantial influence of unique impeller designs on milling efficiency and material consistency. These configurations are specifically crafted to enhance performance, especially in sectors like coatings and inks, where energy conservation and product quality are crucial.

Case studies demonstrate significant improvements in milling outcomes by employing customized impeller setups. The vortex effect they generate during dispersion and bead grinding ensures precise homogenization of particle size distribution, essential for maintaining consistency in paint manufacturing and similar applications.

Choosing the right impeller speed and shape is crucial for effective dispersion of materials within the grinding basket. This decision is key for industries where the integrity of the product is a top priority. Proper technology selection is essential to fine-tune particle size distribution, ensuring that dispersion results align with strict quality standards.

A meticulous understanding of material behavior and processing goals informs the selection of optimal impeller designs in a basket filled with milling beads. This approach guarantees that machinery operates at peak efficiency, with technology decisions playing a critical role in uniform dispersion and the overall success of the manufacturing process.

Factors Affecting Particle Size

While examining the pivotal role of impeller design in milling, it’s crucial to understand other factors like viscosity control and temperature management that significantly influence particle size distribution. Efficient milling practices require meticulous attention to the fluidity of materials, with the dynamics of energy transfer being a focal point.

High levels of viscosity can hinder uniform particle size, making it imperative to utilize solvent composition adjustments and viscosity modifiers. By doing so, it allows for the desired consistency in milling outcomes, thus enhancing the grinding procedures.

Temperature regulation also holds a critical place in effective milling. Excessive heat can result in particle clustering, which disrupts uniformity, while appropriate cooling techniques and speed adjustments in wet grinding promote an even breakdown of particles. Incorporating these strategies, particularly in high-speed mixers and premium dispersers, ensures that milling machinery achieves fine grinding and superior dispersion.

The adaptability and straightforward cleaning of such systems make them exemplary for achieving remarkably fine color pastes through grinding and dispersion processes. The emphasis on using grinding beads offers a path to extremely refined outputs, displaying the hallmark of our superior and customizable products designed to meet specific production requirements.

Enhancing Dispersion Efficiency

Digital controls integrated into high-speed machines revolutionize the dispersion process by offering unmatched precision. These controls optimize energy use and improve mixing reliability, critical for achieving consistent, high-quality results in complex formulations. The introduction of these controls serves as a pivotal advancement, allowing operations to adapt seamlessly and meet demanding standards in the grinding machine sector, particularly with the vma-getzmann systems.

Furthermore, hydraulic lifting dispersers enhance flexibility by accommodating different container sizes. This system adjusts effortlessly, streamlining tasks and enhancing safety with its automated movements. The ability to modify equipment settings according to specific demands makes the manufacturing process more efficient, underscoring the importance of adaptability.

Adopting these advanced methods significantly improves dispersion uniformity, essential for applications requiring consistent viscosity and narrow particle size distribution. The reduction in processing time not only elevates productivity but also ensures product quality is maintained, reinforcing the ethos of continuous development necessary for staying competitive in the highly specialized machinery production market.

Innovations In Grinding Machines

Recent advancements in grinding machine technology, built on the strength of digital controls, are transforming the The grinding machinery used in modern production often includes both bead mills and basket mills for enhanced efficiency. sector. These machines enhance safety and boost operational efficiency. New systems often incorporate advanced grinding equipment to improve overall performance. Automated lifting systems are increasingly utilized in the operation of lab basket mills. and safety interlocks. Such innovations address industry challenges, reducing human error and improving operational consistency.

These technological updates significantly reduce downtime issues while ensuring consistent product quality. Industries like coatings and inks are benefiting from improvements in the performance of the Z-mixer series basket mill. coatings and inks, which require high precision, derive profound benefits. Customizing machinery is a key advantage, allowing equipment to meet specific production needs more efficiently.

Notably, the inclusion of a smaller sieve design within machine systems enables manufacturers to achieve finer particle sizes effectively. This is crucial for companies with unique production requirements demanding high precision. Such flexibility is essential for staying responsive to market demands.

Looking to the future, potential advancements in this field could further enhance the efficacy and accuracy of grinding operations. As firms strive to push technological boundaries, it is anticipated that they will explore how emerging innovations might redefine manufacturing processes, enhancing both productivity and product quality.

| Technological Advancements | Industry Benefits |

|---|---|

| Automated lifting mechanisms | Reduced downtime |

| Safety interlocks | Consistent quality |

| The smaller sieve design is essential for optimizing the performance of milling beads in the wet grinding process. | Finer particle size |