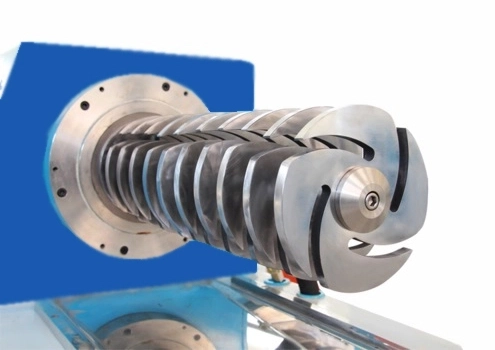

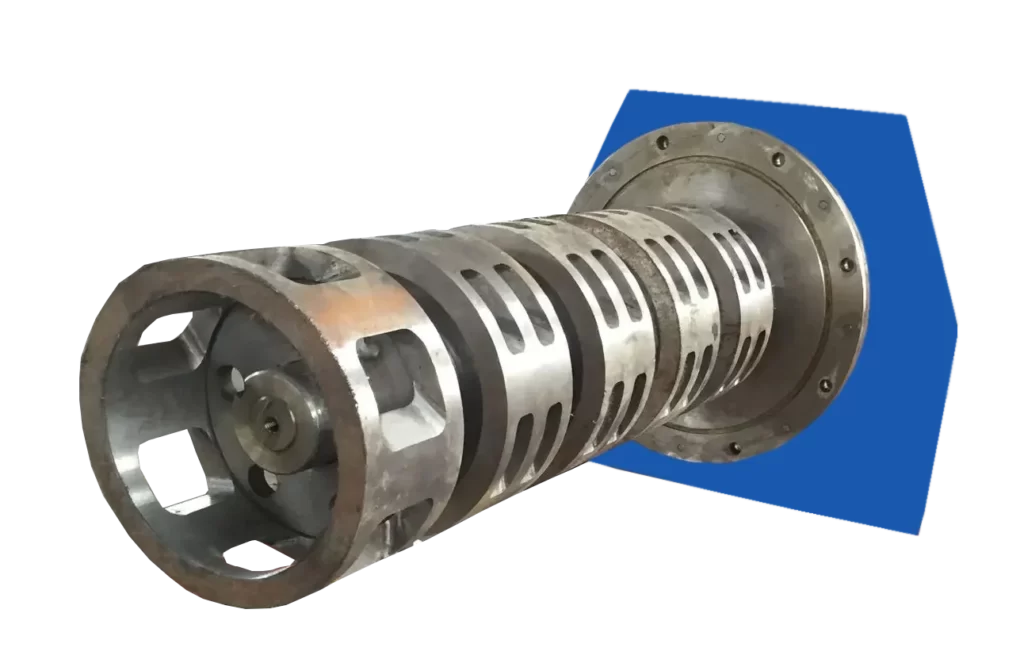

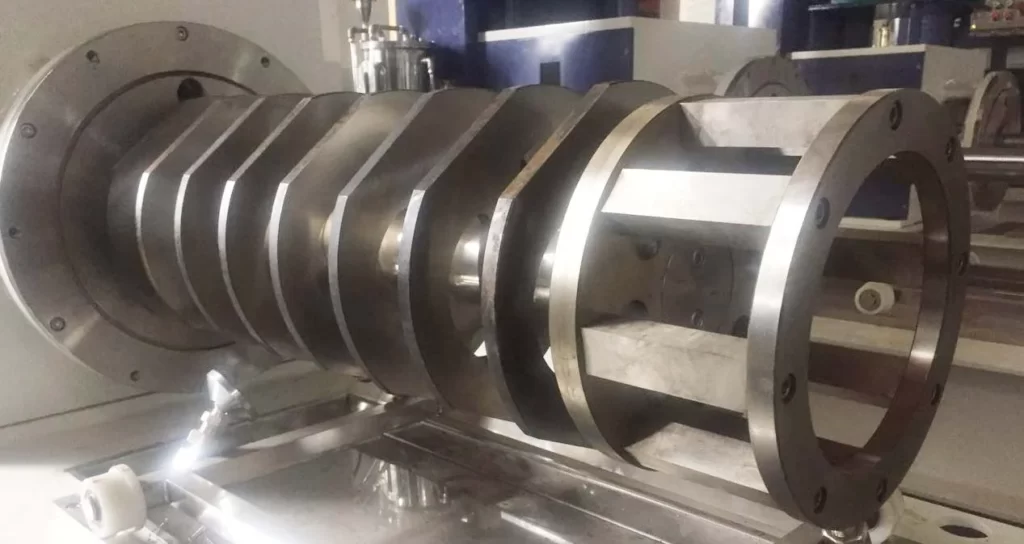

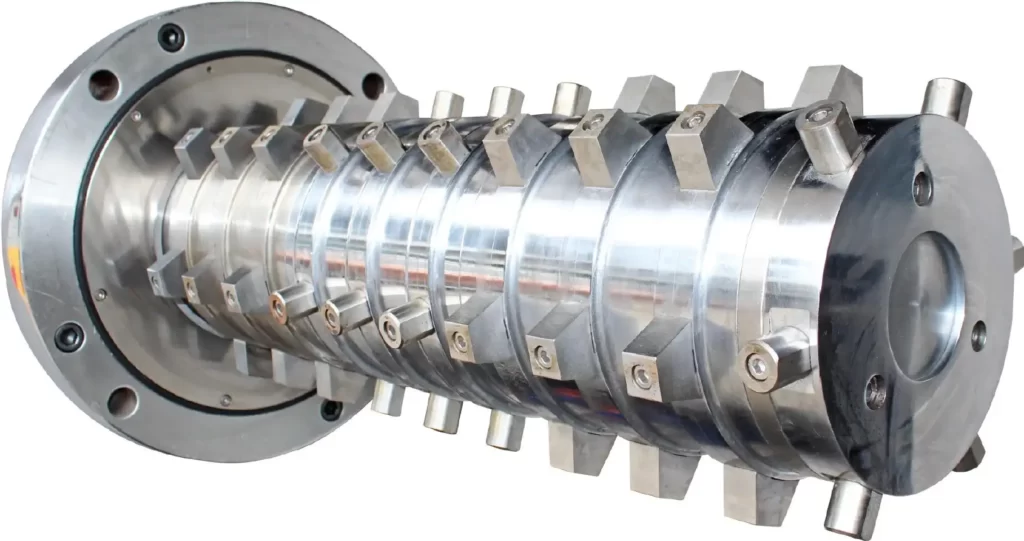

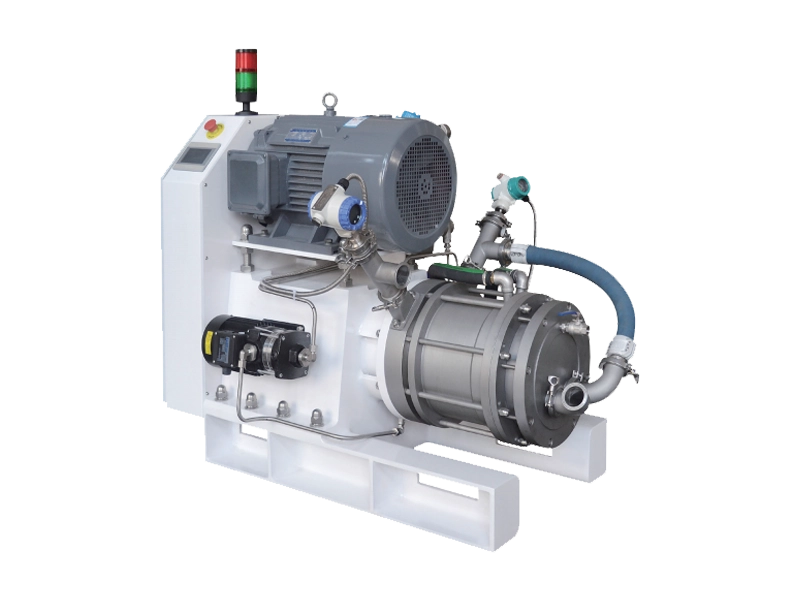

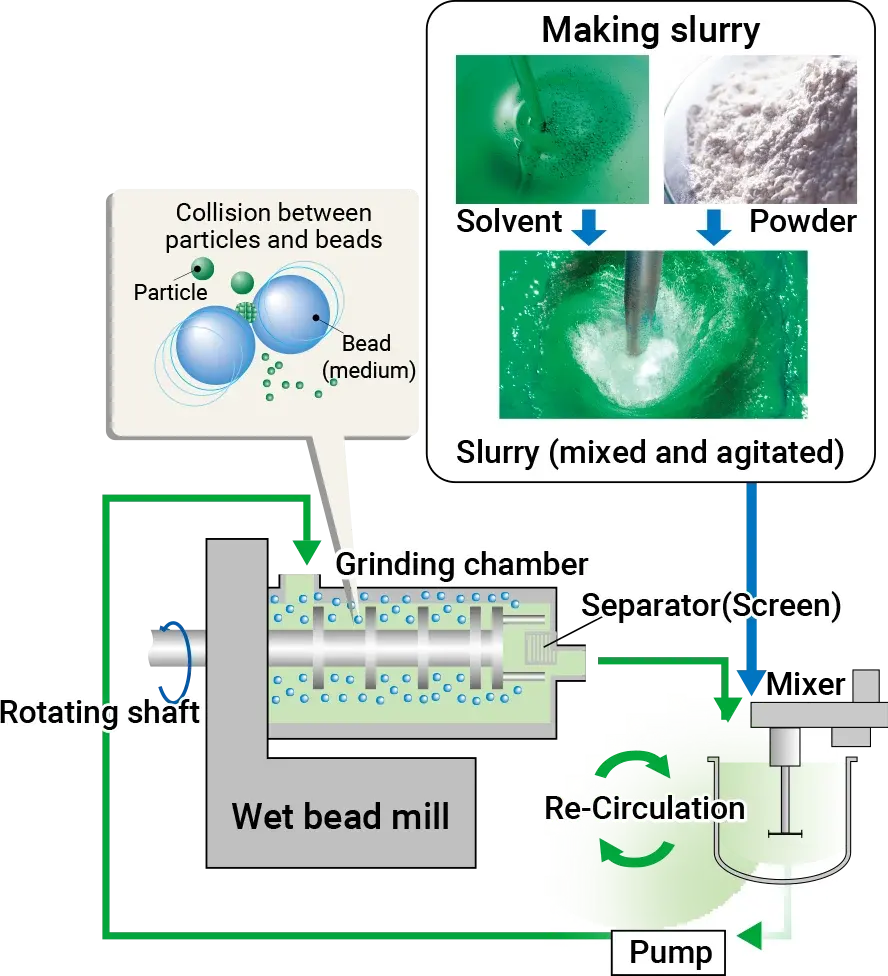

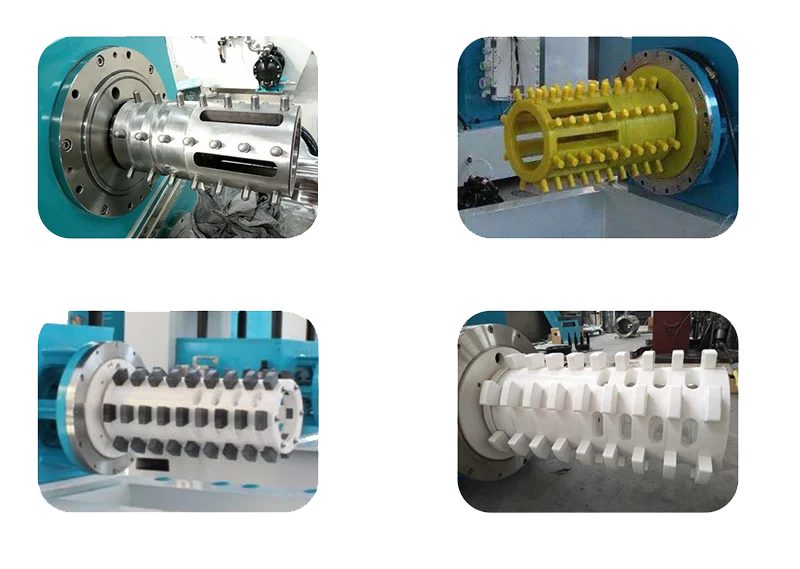

- A Sand mill is consists of a cylindrical chamber filled with grinding beads.

- By continuously pumping the material into the grinding chamber and circulating it through the agitated beads until the desired particle size is achieved.

- The particle size is controlled by adjusting the size of the beads, the speed of agitation, and the duration of the grinding process.

- They are often used for fine grinding and dispersion of pigments, dyes, and other materials that are difficult to disperse using other methods.