Car coating market analysis:

The global high-end functional coatings market is close to 78.5 billion yuan, and the industry space is vast. Coatings are divided into architectural coatings and industrial coatings. High-end functional coatings specifically refer to industrial coatings used in 3C, automobiles, special equipment, etc. in the industrial field. At present, the total market space of the global industrial coatings industry is approximately US$100 billion. The global 3C coatings market space is expected to be 14.3 billion yuan in 2025, with a corresponding demand of 190,300 tons and a CAGR of 2.7%.

In the field of automotive coatings, North America and Europe account for about two-thirds of the global automotive coatings market, maintaining an absolute leading position. Among the top 10 coatings manufacturers in the world, except for Sherwin-Williams and RPM International, their transportation coatings account for a larger proportion. In addition, automotive coatings from other companies such as PPG, BASF, DuPont, AkzoNobel, and Nippon Paint are all its core coating products.

| Automotive coating manufacturing companies | |

| Product area | market situation |

| Original paint | 75%-80% of the market share is occupied by international brands, such as PPG, BASF, DuPont, Kansai, Nippon Paint, etc. They adopt wholly-owned or joint venture methods in China to mainly provide supporting equipment for internationally renowned automobile manufacturers and high-end passenger cars. , and has formed a stable supply chain system.For example, European and American vehicle manufacturing companies (Volkswagen, General Motors, Ford, etc.) are mainly supplied by PPG, DuPont and BASF, while Japanese vehicle manufacturing companies (Handa, Honda, Nissan, etc.) are mainly supplied by Nippon Paint and Kansai Paint , Korean vehicle manufacturing companies (Hyundai, Kia, etc.) are mainly supplied by KCC Company |

| touch up paint | About 75% of the market share is occupied by Chinese independent brands, but most of them are mid- to low-end productsThe main refinish paint manufacturers are: Guangzhou Shichuang, Guangzhou Bonny, Changzhou Planner, PPG, Guangzhou United, Changzhou Fulam, Guangzhou Futian, Guangzhou Yatu, DuPont |

What machines need for building a automatic paint/ car paint?

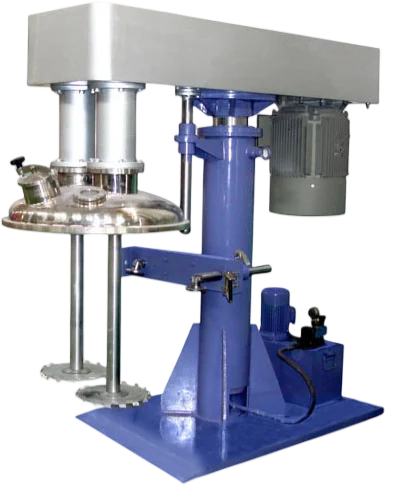

Mixing Equipment:

High-Speed Dispersion Mixer: Used for mixing and dispersing pigments, binders, and other raw materials to create the paint.

Grinding Mills: These are necessary for reducing particle sizes and achieving the desired consistency. Types of mills include basket mill, sand mills.

Filtration System: To remove impurities and ensure a smooth, uniform paint texture.

Filling Machines:

Automatic Filling Machine: For filling paint into cans or containers accurately and quickly.

Capping and Sealing Machines: To cap and seal the filled containers securely.

Labeling Machine: To apply labels with product information and branding to the paint containers.

Packaging Equipment:

Carton Packaging Machine: If you are packaging multiple paint containers together.(optional)

Palletizing Machine: For stacking and wrapping pallets of paint containers for shipping.(Optional, depends on production capacity)

Quality Control Equipment:

Viscosity and Density Measurement Devices: To ensure the paint meets quality standards.

Color Matching and Inspection Equipment: To verify color consistency.

Storage Tanks: To store raw materials, intermediates, and finished paint products.

Pumps and Conveyors: For transferring materials between different stages of production.

Safety Equipment: Ensure you have safety equipment like ventilation systems, fire safety systems, and personal protective equipment for your workers.

Lab Testing Equipment: For quality control and product development, you may need equipment such as lab diseprser, lab sand mill or lab basekt mill, spectrophotometers, viscometers, and rheometers.

Computer Control Systems: To monitor and control the production process for consistency and efficiency.

Utilities: You’ll need a reliable supply of water, electricity, and compressed air for various processes.

Cleaning and Maintenance Equipment: Equipment for cleaning and maintaining the production machinery.

Environmental Compliance Equipment: If applicable, equipment for managing waste and emissions in compliance with environmental regulations.

What machines need for building a car putty/automatic putty?

Dual-Shaft Mixers: These are better suited for high-viscosity materials like car putty. They provide thorough mixing and blending of thick formulations.

Discharge press machine:High-viscosity putty can be challenging to handle manually due to its thickness. A press discharge machine can pump the putty consistently and accurately into containers, reducing the risk of spills and product waste.

Filling Machines:

Gear Pump Filling Machine: Suitable for accurately filling high-viscosity products into containers.

Capping and Sealing Machines: To cap and seal the filled containers securely.

Labeling Machine: To apply labels with product information and branding to the putty containers.

What is car paint/automatic coating?

Car paint refers to the paint sprayed on the car. Car paint is also a type of coating. Spraying paint on a car not only forms a protective film on the surface of the car body, making the car body less susceptible to corrosion, but also prolongs the service life of the car, and also gives people an aesthetic enjoyment.

Different car paints have different effects. Choosing different paint types and colors can show different personalities of the car. Therefore, car paint is very important to the car itself.

Automotive repair coatings are divided into different coatings such as primer, color paint, and varnish. Automobile primer is applied to the body after surface treatment.

The surface provides anti-corrosion, anti-rust, chemical resistance, and water resistance. The paint coat determines the car’s color and is between the base coat and the clear coat. The varnish coating is located on the top layer and provides aesthetic functions such as gloss, fullness, and vividness of the paint surface, as well as protective functions such as weather resistance and corrosion resistance.

| Automobile coating product classification | |

| Depending on the painting object | 1.New car original paint 2. Car repair paint 3. Car paint for various parts 4. Other car paints |

| Press the coating on the car from bottom to Up category | 1.Primer for automobiles, now mostly electrophoretic paint 2. Intermediate coating for automobiles, i.e. intermediate coating 3. Automobile base paint (including solid color base paint and gold paint glitter base paint) 4. Topcoat for automobiles, generally refers to solid color topcoat, which does not require varnishing 5. Automotive varnish 6. Automotive refinishing paint |

| According to paint coating method | 1.Automobile electrophoretic paint 2. Liquid spray paint for cars 3. Automobile powder coating 4. Special coatings for automobiles such as PVC sealing coatings 5. Post-painting treatment materials (anti-rust wax, protective wax, etc.) |

Features

Car paint is different from other paints. Due to the high price of the car itself and the years of experience in spring, summer, autumn and winter, the performance requirements for car paint are extremely high. Car paint must not only have good mechanical properties, good fullness and gloss of the paint film High, it must have good adhesion, high hardness, and strong scratch resistance. At the same time, it must have excellent weather resistance, scratch and wear resistance, gloss sustainability, and excellent resistance to gasoline, alcohol, acid, and Alkali resistance, salt spray resistance and other properties.

Introduction to car surface paint

Automotive paints are generally baking paints. In the car factory, the frame and body are welded, and after the body is repaired by hand, the next process is painting. Generally, the first step is the primer.

The white leather car body is immersed in a syrup-like paint tank, and the primer is taken out and dried; then it is sent to a dust-free workshop, where the topcoat is sprayed using an electrostatic spraying process, and then dried at a temperature of about 200 degrees. Some will also apply a layer of varnish.

Basic ingredients

Automotive paint is mainly composed of resin, pigments, additives, fillers, curing agents, solvents, etc. Metallic automotive paint adds glitter gold powder (aluminum powder), and pearlescent paint adds mica particles.

- Resin (film-forming substance)

- Pigments (including extender pigments, antiseptic pigments, and coloring pigments)

- solvent

- additives

Resin can be divided into : ① natural resin ② artificial synthetic resin (including: thermoplastic, thermosetting, self-crosslinking type)

1. Description of natural resin: secretions from insects or trees. Ingredients: rosin , shellac

2. Description of the thermoplastic properties of synthetic resin: It softens at high temperatures and is easily dissolved by solvents.

Ingredients: vinyl resin, CAB cellulose acetate butyrate, nitrocellulose.

3. Description of thermosetting properties of synthetic resin: It is not easy to soften when heated, has high hardness and is resistant to solvents.

Ingredients: Melamine , epoxy resin, acrylic resin.

4. Synthetic tree self-crosslinking description: A chemical reaction occurs and solidifies when the two components are mixed.

Ingredients: unsaturated resin, polyester resin, polyurethane resin .

Pigment classification : ① anti-corrosion pigments ② extender pigments ③ coloring pigments (inorganic pigments, organic pigments).

1. Anti-corrosion pigments: widely used in primers to enhance anti-corrosion effects.

2. Extension pigment: It improves the thickness and abrasiveness of the paint film and is the main pigment used in primers and other coatings.

3. Coloring pigments: Provide color and hiding power. (Inorganic pigments refer to: metal oxides, usually dark colors. Such as titanium dioxide, iron oxide red and other pigments. Organic pigments refer to: pigments that mainly have bright colors but poor hiding power, such as phthalocyanine blue, adipin red and other pigments. )

Auxiliary : It is a compound with various special properties. Usually, a small amount is added to the paint to obtain or improve the special properties of the paint, but the maximum proportion in the paint does not exceed 5%.

The types of additives include: dispersants, defoaming agents, curing accelerators, anti-shedding additives, softeners, anti-corrosion additives, leveling agents, anti-settling agents, UV absorbers, antioxidants, anti-pinhole agents, etc.

The important role of additives:

Additives are very important for paint, because anything with color may fade under the sun. The same is true for car paint. Its pigments will also fade under the sun. At this time, adding additives to the paint The dose is very important. For example, adding UV absorbers, antioxidants, etc., can prolong the fading time and prevent premature aging of the paint. Many times, the quality of additives determines the quality of paint to a certain extent.

Filler: refers to extender pigments, used in primers to improve the thickness and abrasiveness of the paint film.

Curing agent: used for self-crosslinking resin, which undergoes a chemical reaction and solidifies when the two components are mixed.

Solvent: A liquid with many uses. It can dissolve resin and adjust the viscosity, making it easier to mix pigments and resin, ensuring that the paint has construction viscosity. It can also be used to clean the spray gun and clean excess paint stuck to hands and objects.

Painting process

Automotive paints are generally baking paints. In the car factory, after the frame and shell are welded (and sometimes repaired by hand), the next process is painting. Generally, the first step is the primer. The bare car shell is immersed in the syrup-like paint tank, and the drying primer is taken out; then it is sent to the dust-free workshop and the topcoat is sprayed using electrostatic spray painting technology.

Then dry it at a temperature of about 200 degrees. For more sophisticated ones, another layer of varnish will be applied. In this way, the painting process is complete. There are several general topcoats: ordinary paint; metallic paint; pearlescent paint.

Needless to say, ordinary paint has resins, pigments and additives. The metallic paint contains more aluminum powder; so it looks bright when finished. As for pearlescent paint, mica particles are added. Mica is a very thin piece of material, so the reflection is directional and produces a colorful effect. If it is metallic paint plus a varnish layer, the car’s paint will look bright and beautiful.

In terms of color, white is undoubtedly the cheapest. For example, the world-class brand of red pigment is about 25 times more expensive than the world-class brand of titanium dioxide; while the amount of titanium dioxide in white paint is about 5 times that of red pigment.

Therefore, the color cost of red paint is five times higher than that of white paint. This is why some domestic cars have so few color varieties: simple and low cost.

The importance of additives

No matter what color the paint is, its pigments will fade in the sun. In fact, not only paint, but any colored stuff may fade in the sun. At this time, the additives added to the paint are very important. Such as light stabilizers, antioxidants, etc. Unfortunately, good additives are very expensive.

The quality of the additives determines how the paint feels. People will think that a paint that starts to fade obviously after 2 years is worse than a paint that is still as shiny as new after 5 years. But in reality, no paint does not fade. The factory is more concerned about fading evenly and trying not to cause color differences in different parts of the car.

Related categories

There are two types of automotive paint topcoats:

1. Pure color paint is also called plain paint. The effect of solid color paint is monochromatic, and there are no sparkling particles on the surface when viewed by the eye.

2. Metallic paint : Aluminum powder is added to the paint, and there are sparkling particles on the surface with your eyes. Metallic paint includes silver paint, pearl paint and special pearl paint. Silver powder and pearls have different front and side effects.

Spraying process and operating techniques

Automotive paint spraying process

Good working environment; professional topcoat repair first requires a working environment. Because the biggest concern with spray painting is the impact of dust and impurities. If workers’ dandruff and fibers from clothes fall on the car, spots or bulges will form. A good working environment requires a professional paint booth and computerized paint mixing equipment.

If you want to provide topcoat repair services, you must have special quick repair materials. This quick-drying special material is an important condition to ensure fast topcoat repair. Traditional putty is made of plastic, with rough surface, low hardness, large shrinkage, easy deformation, and long drying time.

What’s particularly bad is that this kind of putty continues to absorb moisture after repairs, and is prone to cracking and sagging. High-tech metal touch-up paint is strong and resistant to high temperatures and can be completely dried within 5 minutes using a quick dryer. Because of its polymer structure, high density, fine surface, no pinholes, and no moisture absorption.

Different operating techniques

1. Different operating techniques There are certain operating techniques for topcoat repair. In order to increase the adhesion of the putty, the parts to be repainted must be polished into a feather shape. Some stores don’t polish it seriously, or even don’t polish it at all. You can imagine how long such putty can last. Topcoat repairs are generally sprayed locally, while varnish needs to be sprayed over a large area to ensure that there is no interface between the repaired area and the original car paint, and there is no trace of repair. 3 Pay attention to sheet metal damage.

If the car has sheet metal damage, it is best to find a place with a sheet metal meson machine to repair it. Because the traditional process uses a hammer to hit, the force is uneven, which can easily cause damage to the car body, and it is difficult to guarantee the flatness. The meson machine uses adsorption to flatten the dented sheet metal, causing less damage to the surrounding area.

Professional topcoat repair first requires a working environment. Because the biggest concern with spray painting is the impact of dust and impurities. If workers’ dandruff and fibers from clothes fall on the car, spots or bulges will form. A good working environment requires a professional paint room and computerized paint mixing equipment.

If you want to perform topcoat repair services, you must have special quick-patch materials. This quick-drying special material is an important condition to ensure fast topcoat repair. Traditional putty is made of plastic, with rough surface, low hardness, large shrinkage, easy deformation, and long drying time. What’s particularly bad is that this kind of putty continues to absorb moisture after repairs, and is prone to cracking and sagging. High-tech metal touch-up paint is strong and resistant to high temperatures, and can be completely dried within 5 minutes using a quick dryer.

Because of its polymer structure, high density, fine surface, no pinholes, and no moisture absorption. Another advantage is that it is formed in one go. Traditional putty requires three layers. Putty that is too thick increases the chance of cracking. Not only the touch-up paint, but also the paint must be of high quality. For example, water-based environmentally friendly paint has strong hiding power and contains UV additives, silver fixatives and antifungal agents to prevent the car paint from fading.

The final step in touch-up paint is to apply varnish. But when it comes to the bright oil on the outer layer of car paint, some touch-up spots don’t spray it at all for the sake of speed. If this is the case, the car paint will lose color and be easily damaged before long. A good quick-drying bright oil with high concentration, no loss of gloss, strong hardness, and not easy to scratch the paint during car washing.

2. Different operating techniques There are certain operating techniques for topcoat repair. In order to increase the adhesion of the putty, the parts to be repainted must be polished into a feather shape.

1.Automobile primers should meet the following technical requirements

| project | index |

| Material status in container | There should be no foreign matter, no hard lumps, and it should be easy to stir into a viscous liquid. |

| Viscosity (6 cups) not less than | 50 |

| The fineness is not greater than | 60 |

| Storage stability, grade no less thanSettabilityCrustiness | 610 |

| Flash point, ℃ not less than | 26 |

| Color and appearance | The color tone is uncertain, the paint film is flat and smooth, matte or semi-glossy |

| Drying time, (h) is not greater thanHard workDrying (120±2℃) | twenty four1 |

| The pencil hardness is not less thanThe cupping test is not less thanPlan each test, level | B50 |

| Polishability, (20 times) | Easy-sanding non-stick sandpaper |

| Oil resistance, (48h) | No obvious change in appearance |

| Gasoline resistance, (6h) | Non-blistering, non-wrinkling, slight discoloration allowed |

| Water resistance, (168h) | No blistering or rusting |

| Acid resistance, (in 0.5mol/L H2SO4, 7h | Non-blistering, non-wrinkling, slight discoloration allowed |

| Alkali resistance, (in 0.1 mol/L NaOH, 7h | Non-blistering, non-wrinkling, slight discoloration allowed |

| Nitrocellulose paint resistance | No biting, no redness |

| Salt spray resistance (168h) level | 2mm outside the cutting line, pass the first level |

| Humidity and heat resistance, (96h) level is not greater than | 1 |

2. Various colored topcoats for automobiles should meet the following technical requirements:

| project | index | ||

| Type I | Type II | Type III | |

| state of matter in container | There should be no foreign matter, hard lumps, and a uniform liquid that is easy to stir up. | There should be no foreign matter, hard lumps, and a uniform liquid that is easy to stir up. | There should be no foreign matter, hard lumps, and a uniform liquid that is easy to stir up. |

| Fineness, not greater than | 10 | 20 | 20 |

| Storage stability, grade no less thansedimentation,Crustiness | 810 | 810 | 810 |

| Plan each test, and the level should not be greater than | 1 | 1 | 1 |

| pencil hardness | H | HB | B |

| Bending test, mm not larger than | 2 | 2 | 2 |

| Gloss (60) not less than | White 85, other colors 90 | White 85, other colors 90 | White 85, other colors 90 |

| Cupping test, mm is not less than | 3 | 4 | 5 |

| Water resistance (240h) | No blistering, no wrinkles, no shedding, slight discoloration, loss of gloss allowed | No blistering, no wrinkles, no shedding, slight discoloration, loss of gloss allowed | |

| Gasoline resistance (4h)(2h) | No blistering, no wrinkles, no shedding, slight discoloration allowed | No blistering, no wrinkles, no shedding, slight discoloration allowed | No blistering, no wrinkles, no shedding, slight discoloration allowed |

| Resistant to temperature denaturation. level not greater than | 2 | agreed | |

| Weather resistance (24 months in Guangzhou area) | There should be no obvious cracks, slight discoloration is allowed, and the gloss loss rate after polishing is ≤30%. | There should be no obvious cracks or discoloration ≤ level 3, and the gloss loss rate ≤ 60% | |

| Artificially accelerated aging (800) | There should be no obvious cracks, slight discoloration is allowed, and the gloss loss rate after polishing is ≤30%. | There should be no obvious cracks, discoloration no greater than level 3, and gloss loss rate ≤60%. | |

| Vividness, Gd value | 0.6–0.8 | ||

Precautions

Configuration purpose

The spray booth is one of the essential equipment for automobile repair and painting operations. The purpose of the equipment spray booth is to provide a clean, safe, and well-lit spray painting environment for automobile painting construction, so that the spray construction is not disturbed by dust, ensure the quality of spray paint, and limit volatile paint mist within a limited space to reduce environmental pollution.

Technical requirements for spray booths

① The air entering the spray booth must be strictly filtered to ensure that there is no dust in the air.

② The air flow in the spray booth must flow from the ceiling to the ground along the direction of gravity, and the air must be discharged from the ground and filtered into cleaner air.

③ Ensure that the air in the spray painting room is converted twice per minute. Therefore, the indoor air flow rate should be 0.3-0.6/s. If the air flow rate is too large, the paint will be lost too much, the coating will be in poor condition, and if the air flow rate is too small, it will affect the normal volatilization of the solvent.

④ Have good lighting conditions.

⑤ Ensure that there is no negative pressure in the spray booth. This can be achieved by controlling the intake and exhaust volume. The amount of air entering the spray booth should be slightly more than the exhaust volume.

⑥ The operating noise in the spray booth is not allowed to exceed 85dB.

⑦Comply with fire protection requirements.

Spray paint classification

Spray booths can be divided into two categories: dry type and wet type according to their different ways of removing paint mist and preventing dust from mixing.

①Dry spray booth. The dry spray booth is mainly composed of chamber body, filter, exhaust pipe and ventilator. It is characterized by simple structure, low paint loss and high painting efficiency. Since it does not use water, it reduces water treatment equipment and has low cost. It is widely used by domestic small and medium-sized repair companies.

②Wet spray booth. Wet spray booths are divided into four types: spray type, water curtain type, Wen type and rotary type. For the painting of high-end automobile topcoats, Wen-type or hydro-rotary spray booths are mostly used in foreign countries, but are rarely used in China.

Spraying method

Color paint spraying method

The pearl silver pink paint is sprayed in three passes: the first pass is a mist spray, and the gun speed can be relatively fast, so that the repair area or the entire car is sprayed as thin as a mist, so that the paint can adhere to the intermediate paint film. The second coat of spraying covers the red and gray layer of paint or putty to show the color. Be careful not to have silver-pink paint stains, blooming and other problems. The speed of the gun can be slightly faster. The third coat of spraying is to correct the uneven spraying such as color spots caused by the second coat of spraying. Generally speaking, the standard is to cover the repair area or the entire car with a uniform color.

How to spray varnish

1. After spraying, wait for the color paint to flash dry for 5 to 15 minutes, so that part of the solvent can evaporate and the coating film becomes dry before spraying. You can spray the clear varnish when you can lightly touch the coating film with your fingers without staining the color. If the painted surface is rough or dust-free. You can use a dust removal cloth and compressed air to wipe it while blowing it. After wiping, degrease with a degreaser (called degreaser in the industry).

2. The first coat of varnish is sprayed mainly with mist spray. It should not be sprayed too thickly. It should be sprayed to a slightly glossy level. The spray gun can be run at a slightly faster speed.

3. The second coat of varnish spraying is for decoration, and it must be sprayed to produce brightness; pay attention to flatness and gloss. Use double-pass (back and forth) spraying method to spray overlappingly, and run the spray gun at a normal or slightly slower speed.

maintenance

① All preparation work before spray painting must be carried out outside the spray booth.

② The filter must be checked frequently and replaced according to the specified time.

③Check the air pressure gauge reading every day to understand the air pressure range in the spray painting room. Negative pressure is strictly prohibited.

④The floor of the dry spray booth must be moistened before spraying to facilitate dust prevention.

⑤ Check lighting conditions regularly and replace weakened or burned out lamps.

⑥ Lubricate and maintain the exhaust fan and motor regularly.

⑦ Pay attention to personal hygiene and it is strictly prohibited to enter the spray booth wearing dirty clothes.

⑧After each painting operation, the relevant equipment in the spray booth should be thoroughly cleaned, maintained and cleaned.

Configuration of paint room

Technical requirements for paint booths.

①The paint room must be clean and dust-free, and the air must be strictly filtered.

②The baking temperature can meet the technical requirements of different coatings.

③ An exhaust device must be installed in the paint baking room so that the solvent and decomposed substances evaporated from the paint film during the drying process do not exceed a certain concentration to prevent the drying speed and quality of the paint film from being affected, or even causing an explosion.

④ A certain amount of time should be allowed for the wet paint film of solvent-based paint before drying to allow most of the solvent in the paint film to evaporate and level, which can reduce defects such as “orange peel”, “pinholes” and “bubbles”.

Classification configuration

According to the different drying methods of the paint film, the paint baking room can be divided into two types: drying type and radiation curing type.

①Drying paint room. Drying paint booths can be divided into three types: natural convection type, circulating fan convection type and far-infrared radiation type. At present, far-infrared radiation paint booths are widely used in domestic maintenance companies. The heating temperature range of far-infrared radiation paint booths is generally 38-83°C.

Automobile maintenance companies can flexibly select the number and number of infrared lamps of the equipment according to the size of the baking operation range. Location. The energy conversion form of far infrared heating is mainly thermal radiation, so compared with the hot air circulation heating method, the possibility of dust adhering to the paint surface is greatly reduced.

Drying the paint surface through far-infrared radiation not only shortens the drying time of the paint film (from one day to 30-50 minutes), improves work efficiency, but also helps to improve the quality of painting construction.

②Irradiation curing paint booth. This kind of paint booth has two types: light curing and electron beam curing, which are rarely used in the general repair and coating industry.

The independent spray booth and paint baking room were introduced earlier. In actual production practice, manufacturers usually combine the spray paint booth and the paint baking room into one, that is, a dual-purpose spray and baking room based on the practicality and economy of the maintenance enterprise.

It has the technical performance and functions of a spray booth and a paint booth. It is characterized by good air purification, and the vehicle to be painted does not need to be moved after painting, which is convenient for construction operations and daily maintenance.

Spray gun configuration

1. Classification and models of spray guns. There are many types and models of spray guns. Although the naming methods of various coating equipment manufacturing companies are different, there are generally the following classification methods.

2. According to the nozzle type, it is divided into two types: counter-nozzle type and flat nozzle type. ② According to the paint supply method, it is divided into three types: siphon type, gravity type and pressure feeding type.

Selection of spray gun: Choose according to the different construction objects of the maintenance company. For the paint spraying of ordinary buses and trucks, you can choose the PQ-1 domestic spray gun, which is low-priced and easy to maintain. For construction with high requirements on coating quality, it is best to use domestic flat-mouth siphon type or imported spray guns.

3. Select large, medium or small spray guns according to the amount of maintenance and construction work. The paint output of small spray guns is less than 100g per minute, the paint output of medium-sized spray guns is about 180g per minute, and the paint output of large spray guns is more than 200g per minute.

4. Choose according to different spraying construction projects. Generally speaking, large-caliber spray guns are mostly used when spraying primers, medium-caliber spray guns are used when spraying intermediate coatings, and small-caliber spray guns are mostly used when spraying topcoats.

5. In special paint repair construction, a special repair spray gun can also be used. Main manufacturers and models of spray guns used for repair abroad.

6. Configuration of spray gun supporting equipment. In painting construction, only the spray gun cannot work. It is also necessary to select appropriate air compressors, air filters and air hoses according to the requirements and construction conditions of the painting construction. Please refer to the relevant instructions of different spray guns. Make specific configurations.