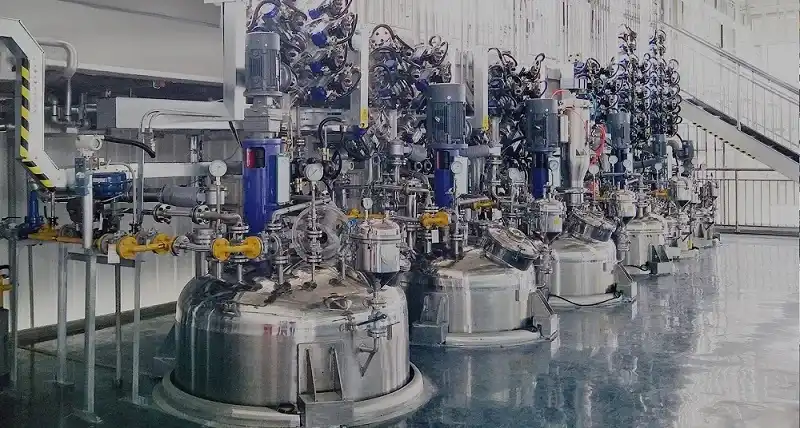

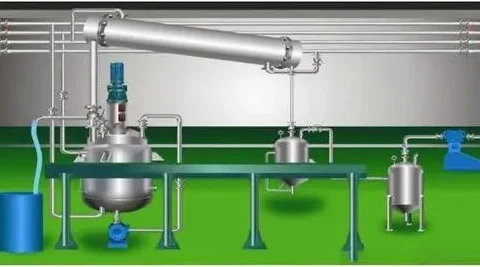

Expoxy resin production line

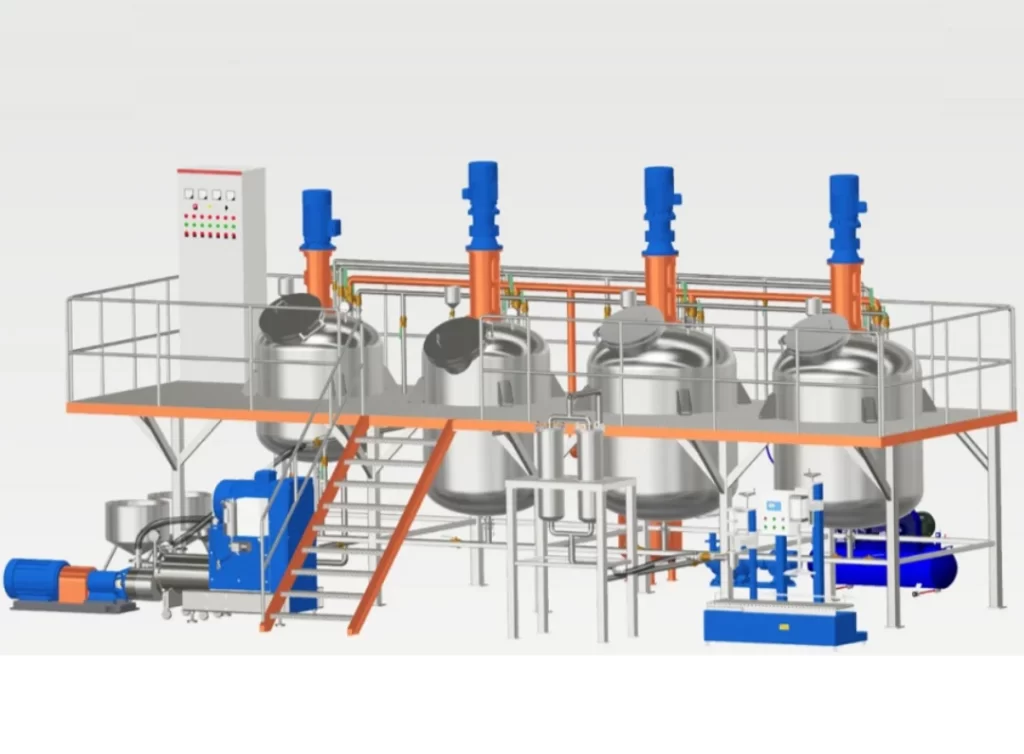

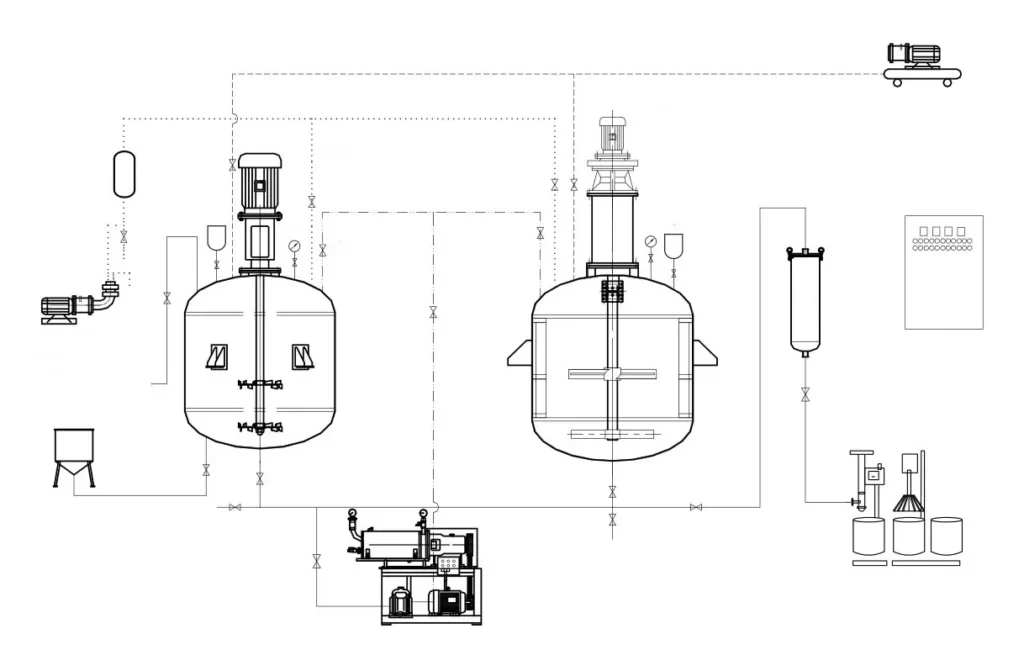

- The epoxy resin manufacturing machines consist of reactor, vertical fractionation column, vertical condenser, horizontal condenser, storage tank, oil overflow tank, high-level tank, dilution tank, pipeline (dilution tank), vacuum unit, etc.

- The epoxy resin making machine main part is a mixing vessel, or call it reactor.

- Mixing vessel is designed for coils or jackets used for cyclic heating or cool.