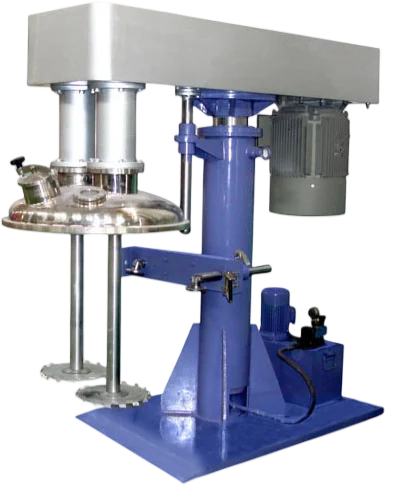

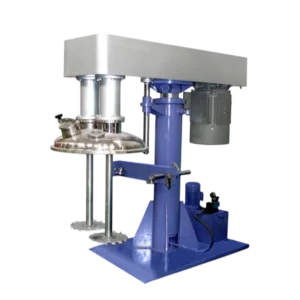

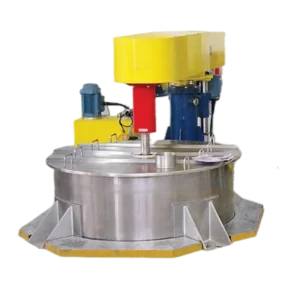

- A high speed disperser is a type of mixing equipment used in various industries such as paint, ink, and chemical manufacturing.

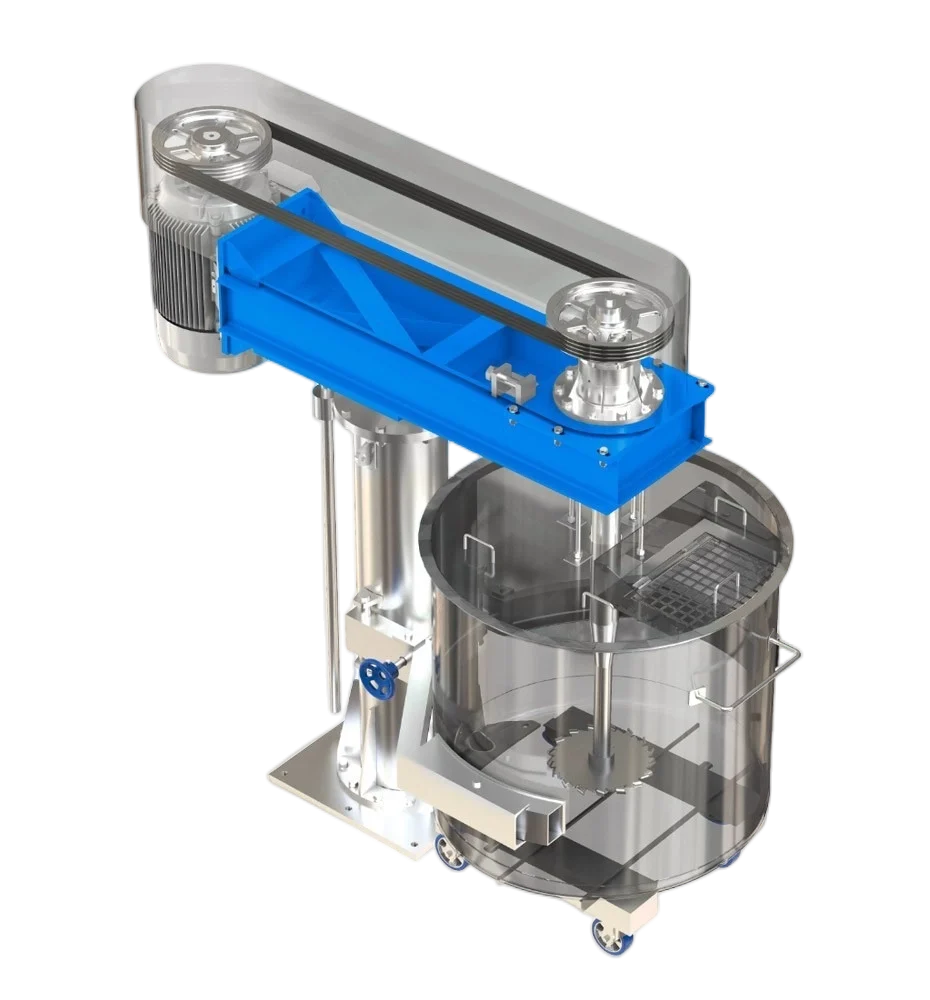

- It consists of a motor-driven shaft with a blade that rotates at high speed to create a vortex in the mixture, which breaks down particles and mixes them together.

- The blade of a high speed disperser is typically a flat disc or saw-toothed design, and can be made of different materials such as stainless steel or coated with various materials depending on the application.

- The speed of the blade can range from a few hundred to several thousand revolutions per minute, allowing for rapid dispersion and mixing of materials.

- High speed dispersers are often used in combination with other mixing equipment such as a vessel or tank to hold the mixture being processed.

- They can be used for various applications such as dissolving solids, creating emulsions, and blending powders.