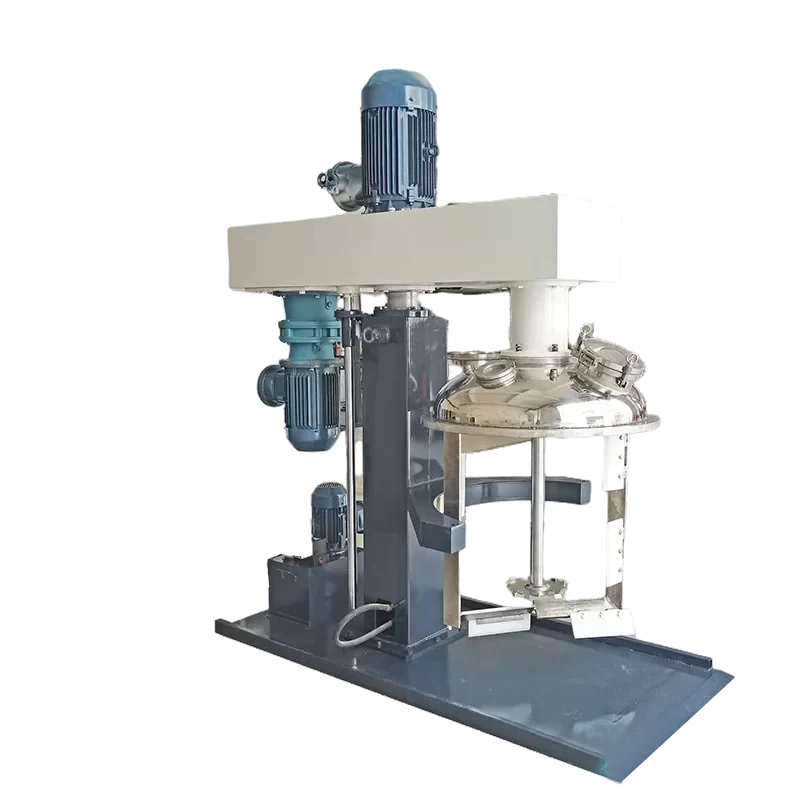

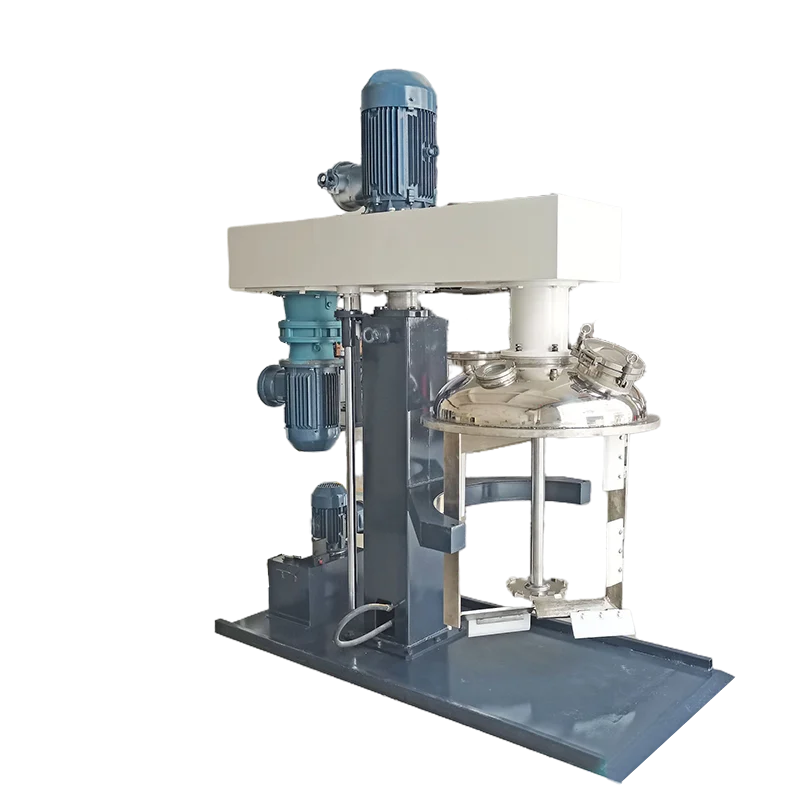

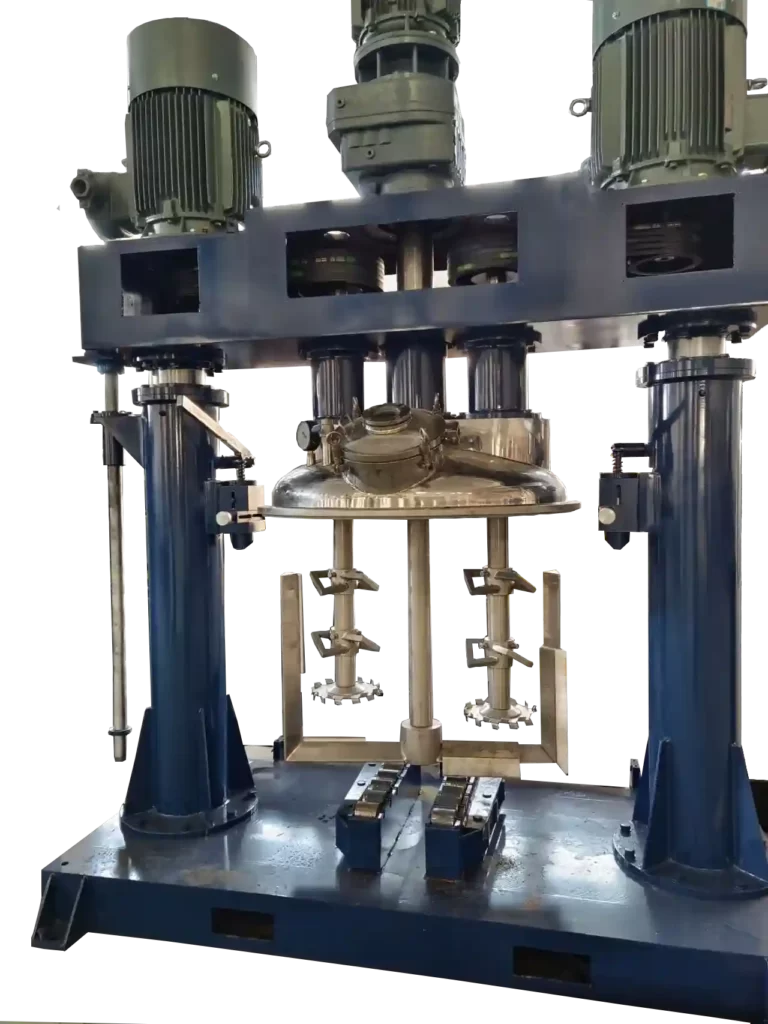

- Multi Shaft Mixer are a type of mixing equipment that is ideal for mixing products with medium to high viscosity.

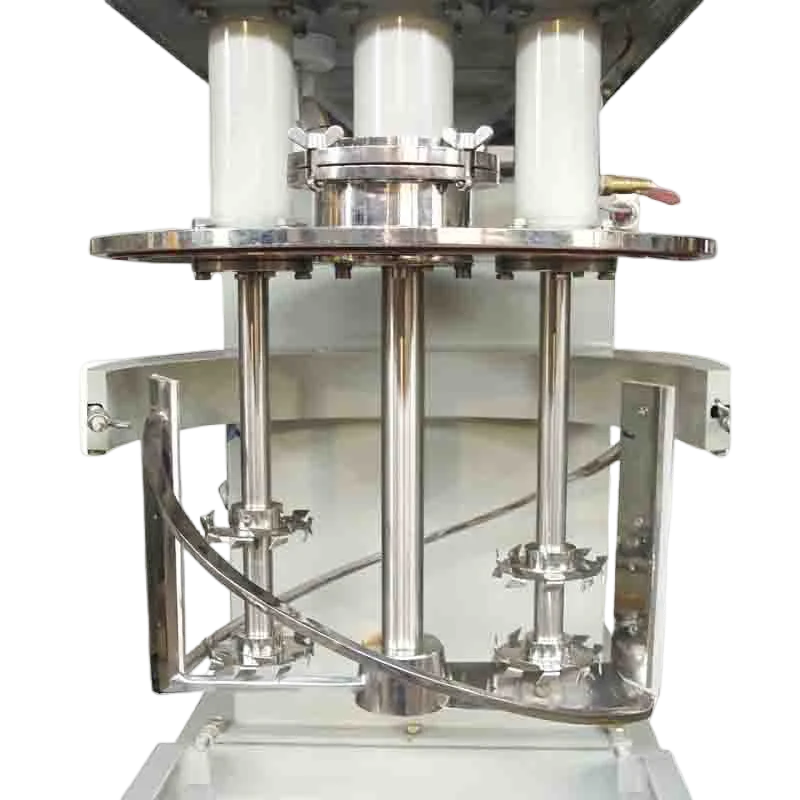

- They consist of Two or three mixing shafts, each with its own set of mixing blades.

- Compared to mixers with just one shaft, the Multi Shaft Mixer design allows for more efficient and thorough mixing of materials.

- In the mixing process, a high-speed disperser alone may have limited effectiveness in viscous products, which is where the low-speed blade comes in.

- It helps to achieve a homogeneous mixture and aids in heat transfer, especially when equipped with scrapers.