Key Takeaways

- To choose the right paint dispenser for water-based emulsion paint, you need to know how these dispensers work. With that knowledge, he can ensure optimal performance and efficiency.

- High-speed dispensers minimize waste and save time during application. This boost in efficiency can greatly enhance productivity in your painting tasks.

- When you’re choosing a dispenser, consider its capacity and how easy it is to use. Ensure it works with your paint type to inform your decision.

- Regularly maintaining and caring for your paint dispenser can greatly extend its lifespan. This not only helps ensure its correct, it also saves you time and money in the long run.

- Familiarize yourself with the technical specifications and features of various dispensers. This knowledge is going to allow you to use them more effectively in your painting tasks.

- Use and maintain dispensers according to best practices. Doing so will enhance your experience of painting and increase your results and happiness with your paintings.

Selecting the right type of dispenser for water-based emulsion paint can change the way you paint. They improve efficiency, provide consistency in application, and minimize waste. Learn about their features and benefits to make better decisions. You’ll learn how to select the ideal dispenser that fits your requirements. You’ll get essential tips on how to use and care for it. This guide aims to equip you with practical insights to perform at an optimal level, ensuring that your next painting project is a breeze.

Understanding Paint Dispensers

What Are Paint Dispensers?

Paint dispensers are critical tools in the paint industry, especially those featuring advanced hydraulic lifting systems. They mix and dispense various types of paints, including water-based emulsions and high speed putty paint. There are two primary categories of paint dispensers: manual and automatic. While manual dispensers require users to mix and dispense products, automatic systems utilize technology to enhance efficiency and precision, making them a popular choice for high-speed applications.

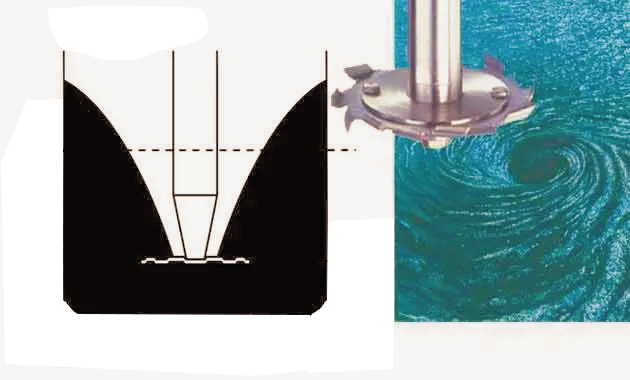

The main components of a paint dispenser include the mixing chamber, pumps, nozzles, and control systems. Within the mixing chamber, the paint and colorants converge to produce the desired color, aided by a high speed disperser that ensures an effective dispersion of materials. Pumps are essential for the precise metering of the paint mixture, particularly when dealing with different paint materials that vary in viscosity. This adaptability is crucial for achieving optimal performance in both water-based and solvent-based formulations.

In commercial and industrial settings, paint dispensers are indispensable. They are frequently employed in automotive refinishing, interior painting, and manufacturing processes that demand color matching accuracy. With thousands of color options available, customer expectations have risen, necessitating the use of efficient and accurate paint dispensing systems. These advanced machines not only enhance work efficiency but also ensure that the final product meets the highest standards of quality.

How Do Paint Dispensers Work?

At the heart of paint dispensers is a metering and dispensing process that utilizes a high-speed disperser for optimal efficiency. The pump mechanism acts as the beating heart of the operation, essential for correct paint dispensing. Advanced technologies, such as DVX pump technology, can triple the life of a colorant pump, significantly reducing costs for businesses that rely on high-speed putty paint production.

Colorants are integrated into the dispensing system, allowing for seamless color matching and a quick dispersing effect. Every four hours, automatic colorant mixing occurs to maximize performance, ensuring that the dispersion of pigments is uniform. Upon request, we can meet special requirements, including modifications for different paint materials premix.

Proper calibration is vital in this process, as it allows for adjustments based on temperature fluctuations or variations in paint viscosity. This meticulous attention to detail ensures that every batch, when mixed, maintains high quality while limiting material waste, ultimately enhancing work efficiency in the paint industry.

Key Features of Paint Dispensers

When selecting a paint dispenser, several key features should be considered to optimize your operations, including the incorporation of a high speed disperser. Automatic dispensing capabilities are a system necessity, and these devices also provide operators with user-friendly interfaces along with programmable settings for customizing mixing processes specific to certain needs. The AccuSmart series introduces significant advancements in precision and accuracy, making them ideal for high speed putty paintapplications. Their ease of use transforms them into perfect training tools for new employees at the store.

Another important factor is the dispenser’s compatibility with various paint types and colorants. A versatile speed dispersion machine can seamlessly integrate into existing workflows, ensuring efficient operations. Compact designs are particularly beneficial, as they conserve precious space in workshops and production areas, contributing to an organized and tidy workspace.

Safety certifications and compliance with industry standards are essential when selecting a dispenser. These certifications help ensure that the equipment meets necessary safety regulations and provides peace of mind regarding operational integrity. Moreover, considering **manual dispensers** with essential functions can enhance the overall user experience and efficiency in the paint industry.

Benefits of High-Speed Dispensers

1. Efficiency in Paint Mixing

Maximizing your efficiency in paint mixing requires evaluating your business or project’s specific needs, particularly when considering a high-speed disperser. This means knowing what kind of hydraulic lifting equipment will fit your scale of operations and the volume needed. If you’re working on larger projects, a high-speed dispersion machine significantly speeds up the paint mixing process, reducing wait times and enhancing productivity. Verify if the disperser accommodates your existing paint systems and gears, allowing for seamless integration into your processes. User feedback and expert recommendations can also significantly improve your selection process, helping you choose a model that provides optimal efficiency while fulfilling your specific requirements.

2. Consistency in Paint Quality

To maintain paint consistency, especially with water-based emulsion paints, first determine the type of paint you’re using. This step is crucial for achieving the best results. Daily monitoring of your paint volume ensures that the chosen manual paint pigment dispenser can keep up with your production demands without sacrificing quality. Automation plays a vital role in this process, as features like a high-speed disperser enhance uniformity over batches, ensuring that each application maintains the same desired texture and hue. When selecting equipment, consider your budget limitations to invest in a solution that is both operationally suitable and financially feasible.

3. Time-Saving in Operations

Time-saving capabilities are essential when considering a hydraulic lifting speed dispersion machine for water-based emulsion paints. Review the technical specifications, including flow rate, canister capacity, and accuracy of dispensing, to gauge how the high-speed disperser can accommodate your operational needs. Comparing dimensions is incredibly important; ensure the model you choose fits well into your workspace to avoid logistical issues. Calculating power supply requirements guarantees compatibility with your facility’s electrical system, which is vital for seamless operation. Additionally, check for self-serviceability and ease of maintenance. These attributes not only save time on labor but also maximize overall productivity by minimizing downtime during the dispersion process.

4. Versatility in Applications

Their ability to work with multiple application methods, including spraying, rolling, or brushing, adds to their versatility in the paint industry. To achieve optimal results, determine your main application methods and align the dispenser’s capabilities with features such as high speed disperser and hydraulic lifting. The viscosity of the paint is critical, affecting the dispersion process and requiring alignment with the available nozzle types and sizes for improved work efficiency and reduced waste.

5. Cost-Effectiveness

Begin with a comparison chart that includes key features, specifications, and prices of the different dispensers, such as a manual paint pigment dispenser or a high-speed dispersion machine. This will help you conduct a cost-benefit analysis effectively. Look at customer reviews and ratings to reveal the performance of various models, especially in terms of their mixing function and quick dispersing capabilities. This process helps us identify those that offer higher efficiency and better quality, particularly in the paint industry. Be sure to consider the warranty and support offered by the manufacturer, as these factors can significantly affect your long-term satisfaction with your investment in hydraulic lifting equipment.

Choosing the Right Dispenser

Identify Your Requirements

Implementing a consistent cleaning plan is essential to maintain your water-based emulsion paint dispenser, ensuring it stays in top shape for high speed dispersion. Begin by outlining a step-by-step cleaning procedure that includes actions like cleaning after each use to prevent cross-contamination of colorants, which can diminish the quality of your work. Remember, even a millimeter can affect the efficiency of your speed disperser, so by adhering to these guidelines, you’ll enhance the durability and performance of your machine.

- Carefully take apart the dispenser components as per manufacturer guidelines.

- Use clean water to rinse out any residual paint from the internal parts.

- Employ cleaning agents that are specifically formulated for use with water-based paints, ensuring they do not react adversely with the materials of your dispenser.

- Regularly check and clean nozzles and hoses to prevent clogs and maintain optimal performance.

To optimize the mixing function, ensure that the equipment is thoroughly cleaned and inspected regularly. This practice not only extends the life of your high speed putty paint disperser but also improves the dispersion of liquid materials, resulting in a better final product. By following these cleaning protocols, you can achieve consistent results and maintain the essential functions of your automatic emulsion paint tinting system, ultimately leading to improved work efficiency in the paint industry.

Evaluate Dispenser Specifications

Frequent inspection of all dispenser components—including pumps, hoses, and nozzles—is necessary to keep it fully functional. Look for standard signs of wear and tear, including cracks, leaks, and decreased flow rates. These signs might indicate it’s time for replacements or repairs. To streamline your maintenance process, consider using this checklist during inspections:

- Check pump integrity

- Inspect hose connections for leaks

- Examine nozzle condition

- Test flow rate consistency

Confront wear problems as quickly as possible to avoid time loss. This approach ensures your projects run like clockwork and don’t run into unexpected downtime.

Consider Application Methods

The type of lubricants for certain parts of your dispenser greatly affects its efficiency. Build a lubrication schedule that corresponds to how often you use your product. This schedule should include:

- Lubricating moving parts regularly

- Checking compatibility of lubricants with water-based paints

Replacing worn out parts in a timely manner will be key to continued efficiency. Check the manufacturer recommendations or reputable suppliers when looking for compatible replacement parts for your dispenser model. That way, you can make sure you’ll be getting parts that meet both compatibility and quality standards.

Compare Different Models

When hydraulic lifting dispensers aren’t in use, proper storage practices are essential to prevent damage and prolong their lifespan, ensuring the equipment remains durable for high-speed dispersion tasks.

- To prevent corrosion, store dispensers in a clean, dry environment.

- Secure dispensers to avoid accidental tipping or falling.

- Cover dispensers to shield them from dust and contaminants.

Maintenance and Care Tips

Regular Cleaning Procedures

Cleaning your water-based emulsion paint dispenser regularly is essential for maintaining its functionality and ensuring a smooth operation, especially in the paint industry. Begin by disassembling the dispenser according to the manufacturer’s instructions, which typically involves removing the nozzle, cap, and any additional removable pieces. Thoroughly clean these parts with warm soapy water to prevent any paint residue from hardening and blocking the flow. Pay extra attention to the nozzle, as this is where clogging is most likely to occur. A soft brush or a pipe cleaner may be especially helpful to dislodge stubborn paint build-up. After washing, rinse all components with clean water and allow them to dry completely before reassembly. This routine cleaning should be performed after every use or at least once a week, ensuring the longevity of your high-speed disperser and its essential functions.

Inspecting for Wear and Tear

Regularly examine your hydraulic lifting dispenser for signs of wear and tear that may interfere with its performance. While conducting these assessments, watch for cracks or warping in the body of the machine, which can cause leaks. Check seals and gaskets for wear; these parts are vital for holding pressure and preventing leaks during the dispersion process. Additionally, examine hoses and fittings, ensuring they are holding tight and showing no signs of wear. Spacing out your inspections helps you discover problems before they escalate, enabling timely repairs or replacements and ultimately saving you from more significant issues down the line.

Lubrication and Parts Replacement

Lubricating moving parts inside your speed dispersion machine is crucial for peak performance and longevity. Apply a food-safe lubricant to any joints or mechanisms that need it, as this will reduce friction and wear during operation. It’s also essential to proactively replace worn-out parts, especially if you notice that the hydraulic lifting mechanism is struggling to work properly. Addressing this issue promptly will help you keep track of when you last replaced critical components and prevent future problems. Regular lubrication, coupled with timely part replacements, ensures that your disperser operates smoothly for an extended period.

Storing Dispensers Properly

The way you store your manual paint pigment dispenser can significantly impact its overall lifespan and usability. When not in use, it’s best to store the speed dispersion machine in a cool, dry place to prevent damage. Avoid exposure to sunlight and extreme temperatures, as these conditions can cause the plastic parts to warp over time. If possible, keep the dispenser upright to prevent any residual paint from leaking into unwanted areas. Covering the dispenser with a dust cloth or placing it in a container will help keep it dust-free and ready for your next project. By adhering to these storage guidelines, you’ll ensure your equipment remains in excellent condition for efficient liquid dispersion during your future endeavors.

Conclusion

Picking the best dispenser for water-based emulsion paint can make a noticeable difference in your comfort and overall quality. You have a good idea of various types of dispensers. Now that you know their benefits and maintenance tips, you’re ready to make an informed decision that suits your specific needs. A high-speed dispenser is an investment that can help simplify your process. Whether you’re a pro or just getting started, it will make you more productive. Remember, a little maintenance goes a long way to make your car last longer and perform its best.

Whether you’re ready to elevate your painting projects, read more about paint dispensers at Home Depot. Check out the options on the market, and choose one that suits your style and workflow. Let’s keep those paint jobs smooth and flawless!

Frequently Asked Questions

What is a paint dispenser?

A paint dispenser is a device that accurately measures and dispenses paint, particularly water-based emulsion paints, ensuring even application and minimizing waste while enhancing the speed dispersion machine’s efficiency for quick dispersing of liquid materials.

How do high-speed dispensers work?

High-speed dispensers utilize precise technology for quick dispersing of paint, enhancing productivity and efficiency in painting projects while ensuring a smooth and effective dispersion process.

What should I consider when choosing a paint dispenser?

When selecting a suitable manual paint pigment dispenser, consider paint type, dispensing speed, and ease of use to enhance workflow and maintain high quality in the paint industry.

How can I maintain my paint dispenser?

Be sure to clean the manual paint pigment dispenser routinely after each use, examine the pump for signs of clogging, and check for wear on the oil seals. Proper maintenance helps you get the most out of your hydraulic lifting equipment in the long run.

Are there any safety tips for using paint dispensers?

Always wear protective gear, such as gloves and masks, and ensure adequate ventilation in your working area to prevent inhaling fumes from liquid materials like paint or cleaning solvents.

Can I use a paint dispenser for other liquids?

Some dispensers, including the high speed disperser, handle other viscous liquids. Check the manufacturer’s specs to see if it can work with different paint materials premix or other materials.

Where can I buy a reliable paint dispenser?

The best places to buy reliable paint dispensers, such as a manual paint pigment dispenser or a speed dispersion machine, are home improvement stores, specialized paint suppliers, or online retailers, ensuring a quality choice for users.